Equipment Lifecycle Management in Databases

In the realm of industrial operations, the effective management of mechanical equipment is vital for ensuring both efficiency and longevity. One of the key strategies that organizations are increasingly adopting is Equipment Lifecycle Management, and the role of databases in driving this process is paramount. In this blog post, we will explore the significance of Equipment Lifecycle Management in Databases, delve into the realm of database-driven equipment maintenance, and understand the importance of lifecycle data tracking for mechanical equipment.

Equipment Lifecycle Management in Databases

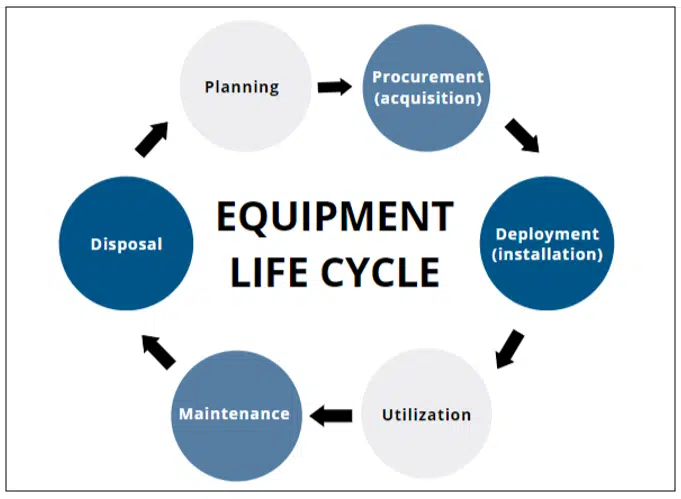

Equipment Lifecycle Management (ELM) is a comprehensive approach to managing the entire lifespan of industrial equipment – from acquisition and installation to operation, maintenance, and eventual decommissioning. In the digital age, the integration of databases into this process has revolutionized the way organizations handle their assets. Here are some key aspects that highlight the importance of Equipment Lifecycle Management in Databases.

Centralized Data Repository

Databases provide a centralized repository for storing all pertinent information related to equipment, including specifications, maintenance history, and performance metrics. This centralized approach facilitates easy access to critical data, promoting better decision-making throughout the equipment lifecycle.

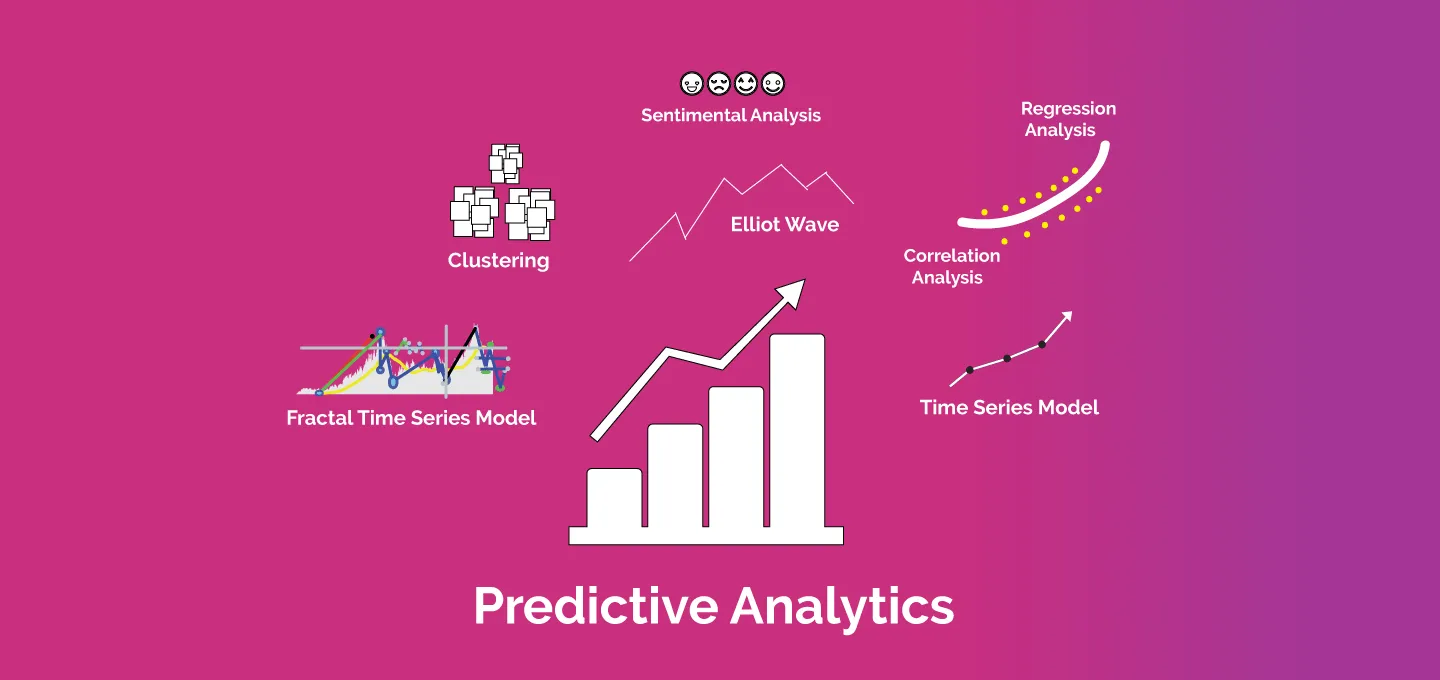

Predictive Maintenance

By utilizing historical data stored in databases, organizations can implement predictive maintenance strategies. This involves analyzing patterns of equipment behavior to predict potential failures, allowing for proactive maintenance and minimizing downtime.

Cost Optimization

ELM databases enable organizations to track costs associated with each phase of the equipment lifecycle. This data-driven approach allows for better budgeting, cost forecasting, and the identification of areas where operational efficiency can be improved.

Regulatory Compliance

Many industries are subject to stringent regulatory requirements. ELM databases streamline compliance efforts by providing a comprehensive record of equipment maintenance and performance, ensuring that organizations adhere to industry standards and regulations.

Database-Driven Equipment Maintenance

The advent of advanced databases has transformed traditional approaches to equipment maintenance. Database-driven equipment maintenance is a proactive and data-centric method that leverages the capabilities of modern database systems. Here’s a closer look at why organizations are increasingly relying on database-driven maintenance practices.

Real-time Data Accessibility

Databases provide real-time accessibility to critical equipment data, allowing maintenance teams to make informed decisions on the fly. This ensures that maintenance activities are aligned with current equipment conditions and operational requirements.

Customized Maintenance Plans

With detailed historical data at their disposal, organizations can tailor maintenance plans based on the specific needs and usage patterns of each piece of equipment. This personalized approach enhances the efficiency of maintenance activities and prolongs equipment lifespan.

Work Order Management

Database-driven maintenance facilitates streamlined work order management. Maintenance teams can create, track, and manage work orders efficiently, ensuring that all maintenance tasks are executed in a timely manner.

Integration with IoT Sensors

The integration of databases with Internet of Things (IoT) sensors allows for real-time monitoring of equipment conditions. These sensors collect data on factors such as temperature, vibration, and usage, providing insights that contribute to more effective maintenance strategies.

Lifecycle Data Tracking for Mechanical Equipment

Accurate and comprehensive lifecycle data tracking is the linchpin of successful Equipment Lifecycle Management. This process involves capturing, storing, and analyzing data at every stage of a piece of mechanical equipment’s life. Let’s explore why meticulous data tracking is a game-changer for organizations

Performance Analysis

Lifecycle data tracking allows organizations to conduct in-depth analyses of equipment performance over time. This includes evaluating efficiency, identifying patterns of wear and tear, and assessing the impact of various operating conditions on performance.

Warranty and Service History

Maintaining a detailed service history for each piece of equipment aids in warranty management and ensures that maintenance activities align with warranty requirements. This, in turn, can lead to cost savings and improved collaboration with equipment manufacturers.

Resale and Decommissioning Planning

As equipment nears the end of its operational life, comprehensive lifecycle data becomes invaluable for resale or decommissioning planning. Organizations can make informed decisions about whether to retire, refurbish, or sell equipment based on its historical performance and remaining lifespan.

Continuous Improvement

Data tracking enables organizations to identify areas for improvement in equipment design, operation, and maintenance practices. This iterative process of continuous improvement ensures that future equipment investments are more strategic and aligned with organizational goals.

Equipment Reliability in Database Systems

In the realm of industrial settings, equipment reliability is synonymous with operational continuity and efficiency. The marriage of reliable equipment with sophisticated database systems creates a synergy that empowers organizations to achieve unparalleled levels of performance. Let’s delve into the key aspects that highlight the importance of equipment reliability in database systems.

Real-time Monitoring and Alerts

Database systems equipped with real-time monitoring capabilities provide a continuous stream of data on equipment performance. This allows organizations to identify potential issues or deviations from normal operating conditions promptly. With the aid of alerts, maintenance teams can address these issues before they escalate, minimizing downtime and optimizing reliability.

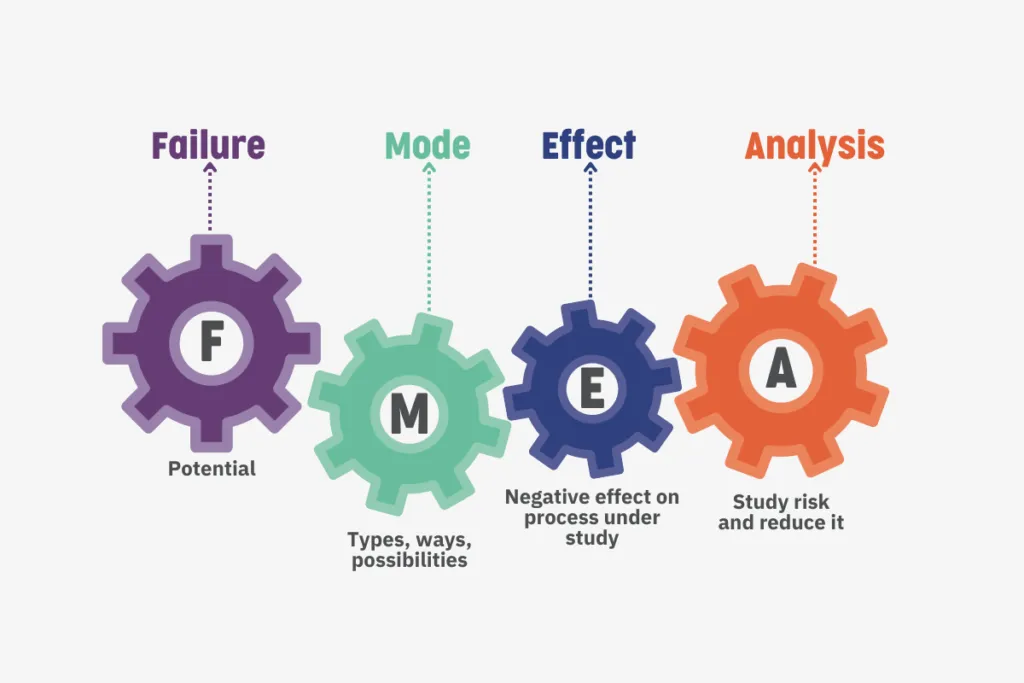

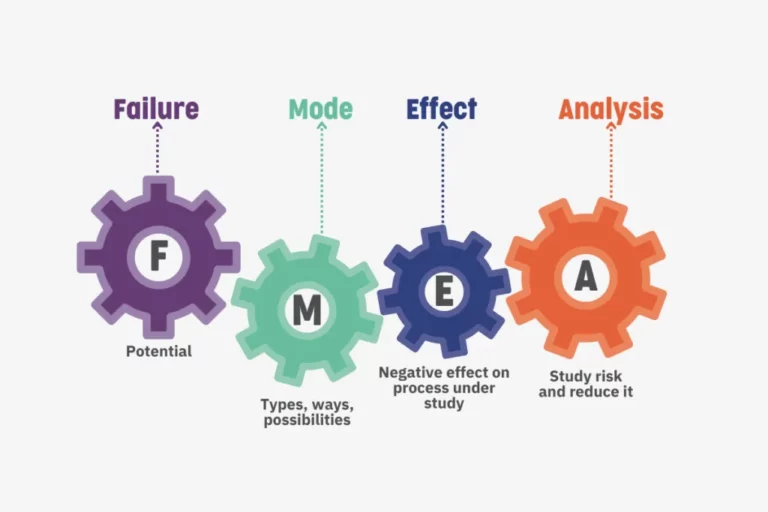

Predictive Analytics for Maintenance

Advanced database systems leverage predictive analytics to forecast potential equipment failures based on historical data. By analyzing patterns and trends, organizations can implement proactive maintenance strategies, replacing components or addressing issues before they lead to unexpected breakdowns. This predictive approach enhances overall equipment reliability.

Performance Metrics and Trend Analysis

Database systems store a wealth of performance metrics over time. Analyzing this data enables organizations to identify trends in equipment behavior, allowing for informed decision-making. Whether it’s optimizing operational parameters or upgrading components, these insights contribute to sustained equipment reliability.

Historical Data for Continuous Improvement

A reliable database system becomes a treasure trove of historical data. Organizations can use this data to conduct root cause analyses of past issues, enabling continuous improvement in equipment design, operation, and maintenance practices. This iterative process ensures that reliability is an evolving aspect of industrial operations.

Asset Lifecycle Planning in Databases

Effective Asset Lifecycle Planning is the strategic roadmap that organizations follow to maximize the value and efficiency of their assets from acquisition to decommissioning. The role of databases in this process is pivotal, providing a structured and data-driven approach. Let’s explore the key elements of Asset Lifecycle Planning in Databases.

Centralized Data Repository

Databases serve as a centralized repository for all asset-related information, including specifications, maintenance records, and performance metrics. This consolidation facilitates easy access to critical data, ensuring that stakeholders have a comprehensive understanding of each asset’s history and current status.

Strategic Planning and Budgeting

Asset Lifecycle Planning involves strategic decision-making regarding asset acquisitions, upgrades, and retirements. Databases enable organizations to create detailed plans and budgets based on historical data, performance metrics, and regulatory compliance requirements.

Risk Mitigation

Databases provide a platform for organizations to assess and mitigate risks associated with asset management. By analyzing historical performance data and incorporating predictive analytics, organizations can identify potential risks and develop proactive strategies to mitigate them, ensuring a smoother asset lifecycle.

Integration with Maintenance Strategies

Asset Lifecycle Planning in databases seamlessly integrates with maintenance strategies. By aligning maintenance activities with the planned lifecycle stages, organizations can optimize the performance and reliability of assets throughout their operational life.

Equipment Tracking and Management Software

In an era where data drives decision-making, Equipment Tracking and Management Software have become indispensable tools for organizations seeking efficient and proactive asset management. Let’s explore the key features and benefits of this software.

Inventory Visibility

Tracking software provides real-time visibility into the entire inventory of equipment. This includes details on each asset’s location, usage history, and current status. This visibility is crucial for efficient asset utilization and resource allocation.

Maintenance Scheduling and Work Orders

Equipment tracking software enables organizations to schedule maintenance activities and generate work orders seamlessly. This streamlines the maintenance process, ensuring that tasks are executed in a timely manner, contributing to enhanced equipment reliability.

Compliance and Documentation

Compliance with industry standards and regulations is a paramount consideration for organizations. Equipment tracking software facilitates the documentation of maintenance activities, certifications, and inspections, ensuring that assets are consistently in compliance with regulatory requirements.

Performance Analytics

Tracking software provides performance analytics that go beyond simple tracking. Organizations can analyze data to gain insights into equipment efficiency, utilization rates, and overall performance. These analytics support informed decision-making for optimizing asset performance.

the integration of equipment reliability in database systems, Asset Lifecycle Planning in databases, and Equipment Tracking and Management Software lays the foundation for a proactive and streamlined approach to industrial asset management. Organizations that leverage the power of data-driven decision-making and strategic planning are better equipped to ensure the reliability, efficiency, and longevity of their assets. As technology continues to evolve, the synergy between reliable equipment and advanced database systems will play a pivotal role in shaping the future of industrial operations.

Conclusion

the integration of databases into Equipment Lifecycle Management is a transformative step toward achieving operational excellence, cost optimization, and sustainability. By leveraging the power of data, organizations can proactively manage equipment maintenance, extend the lifespan of assets, and make informed decisions that contribute to overall efficiency. As industries continue to embrace digitalization, database-driven equipment maintenance and lifecycle data tracking will undoubtedly play a central role in shaping the future of industrial asset management.