Historical Data Analysis for Mechanical Systems

Historical data analysis for mechanical systems is a crucial aspect of understanding, optimizing, and maintaining the performance of various mechanical components and systems over time. This process involves collecting, organizing, and scrutinizing past data to identify patterns, trends, and anomalies that can provide valuable insights into the behavior and health of mechanical systems.

Historical Data Analysis for Mechanical Systems

One key objective of historical data analysis in the realm of mechanical systems is predictive maintenance. By analyzing the historical performance data of machines and equipment, engineers can anticipate potential failures and schedule maintenance activities proactively, minimizing downtime and reducing overall maintenance costs. This predictive approach enhances the reliability and efficiency of mechanical systems, preventing unexpected breakdowns and extending the lifespan of components.

Analyzing historical data also allows engineers to optimize the design and operation of mechanical systems. By studying past performance trends, engineers can identify areas of improvement, refine designs, and implement changes to enhance efficiency and functionality. This iterative process is essential for continuous improvement and innovation in mechanical engineering.

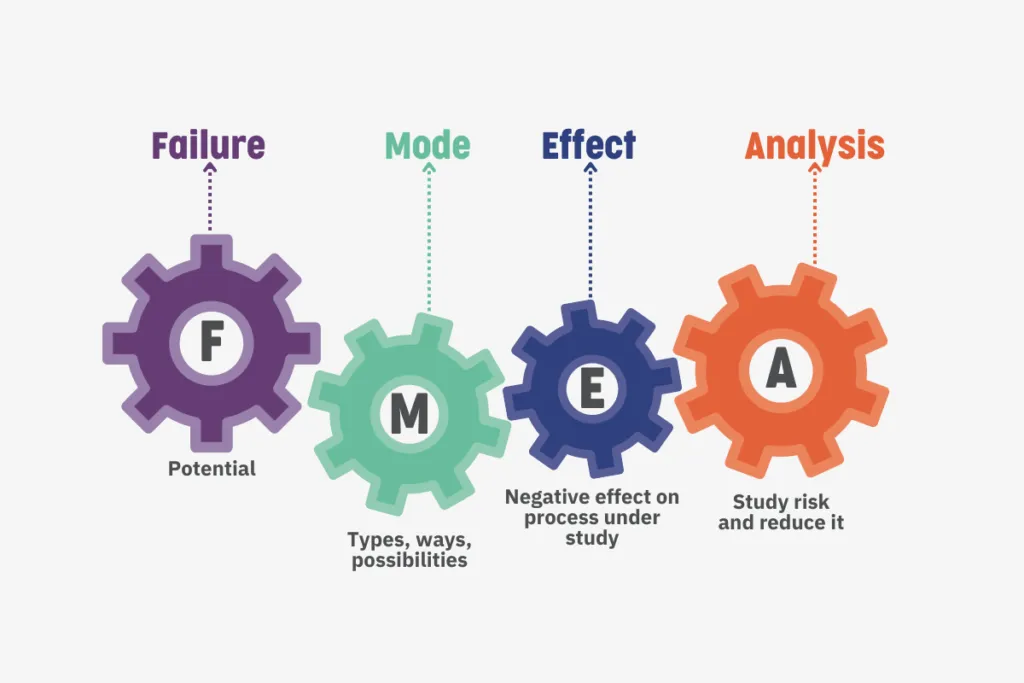

Furthermore, historical data analysis plays a vital role in troubleshooting and root cause analysis. When mechanical systems experience failures or malfunctions, examining historical data can help engineers pinpoint the exact moment or conditions leading to the issue. This retrospective analysis aids in diagnosing problems accurately and implementing effective solutions, preventing similar issues in the future.

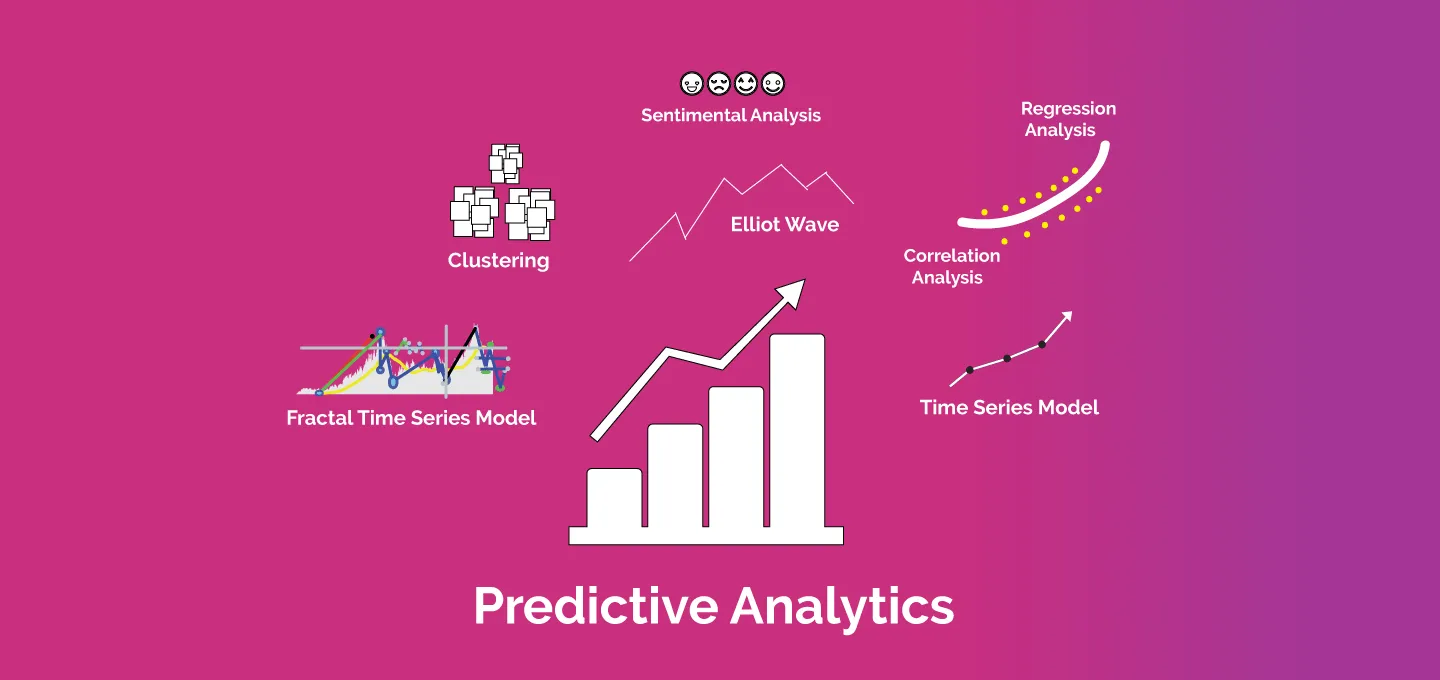

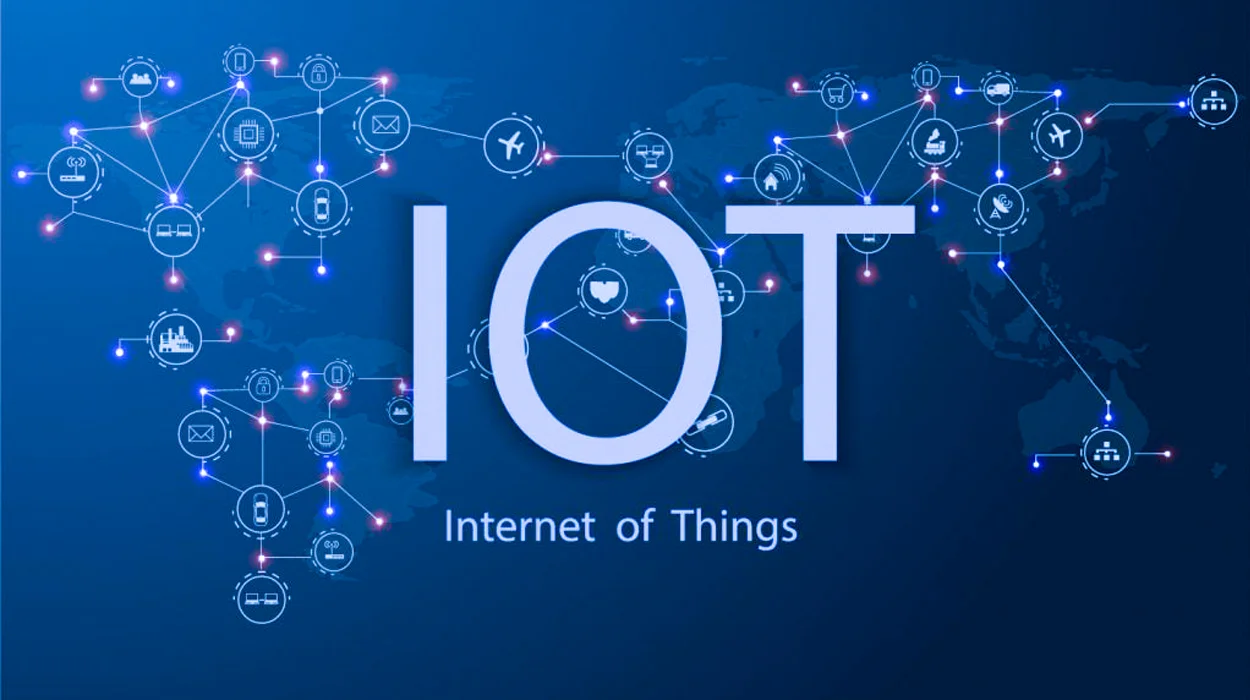

To conduct historical data analysis effectively, engineers utilize advanced tools and techniques, including statistical analysis, machine learning algorithms, and data visualization. These tools enable them to extract meaningful information from large datasets, identify trends, and make informed decisions based on data-driven insights. The integration of sensor technologies and IoT (Internet of Things) devices in mechanical systems further enhances data collection, providing real-time and high-frequency data for more accurate analysis.

Historical data analysis is integral to the field of mechanical engineering, offering valuable insights for predictive maintenance, system optimization, and issue resolution. By harnessing the power of data, engineers can ensure the reliability, efficiency, and longevity of mechanical systems, contributing to advancements in technology and industry.

Analyzing Historical Data Trends in Mechanical Systems

Analyzing historical data trends in mechanical systems is a dynamic process that involves studying patterns and variations in past data to gain a deeper understanding of system behavior and performance. This analytical approach provides engineers with valuable insights into the factors influencing mechanical systems over time, enabling them to make informed decisions for optimization, maintenance, and innovation.

One key aspect of analyzing historical data trends is the identification of recurring patterns. Engineers examine historical performance data to detect regularities or cycles in system behavior. This understanding helps in predicting future trends and optimizing operational parameters to enhance efficiency. For example, in manufacturing processes, analyzing historical trends can reveal production cycles, allowing engineers to schedule maintenance during downtime and minimize disruptions.

Variability analysis is another critical component of studying historical data trends. By examining fluctuations in mechanical system data, engineers can identify potential sources of instability or inefficiency. This analysis is particularly important in ensuring the robustness and reliability of systems, as it enables engineers to address issues related to variability and implement measures to stabilize performance.

Analyzing historical data trends also facilitates the identification of outliers or anomalies. Sudden deviations from established patterns may indicate malfunctions or abnormalities in the system. Engineers can use this information to conduct thorough investigations, identify root causes, and implement corrective actions to prevent similar occurrences in the future. This proactive approach to anomaly detection is essential for maintaining the integrity and reliability of mechanical systems.

The integration of advanced analytics tools and machine learning algorithms enhances the accuracy and efficiency of historical data trend analysis. These tools can process large datasets quickly, identify complex patterns, and provide predictive models for future system behavior. The use of artificial intelligence in trend analysis contributes to more effective decision-making and optimization strategies.

Furthermore, historical data trend analysis is instrumental in research and development efforts. Engineers can review past data to assess the performance of prototypes, experiment with different design parameters, and refine models for better efficiency and functionality. This iterative process of analysis and improvement drives innovation in mechanical systems, leading to the development of more advanced and reliable technologies.

Analyzing historical data trends in mechanical systems is a multifaceted approach that involves identifying patterns, studying variability, and detecting anomalies. This process empowers engineers to make data-driven decisions for optimization, maintenance, and innovation, contributing to the continual advancement of mechanical engineering.

Historical Data Storage and Retrieval in Databases

The storage and retrieval of historical data in databases play a pivotal role in maintaining a comprehensive record of the performance, maintenance, and behavior of mechanical systems over time. Properly managed historical data serves as a valuable resource for engineers, researchers, and decision-makers, providing a foundation for analysis, optimization, and informed decision-making.

Efficient historical data storage is characterized by organized and well-structured databases. Engineers design databases to store various types of data, including sensor readings, maintenance logs, and performance metrics. Categorizing data in a systematic manner facilitates easy retrieval and analysis, ensuring that valuable information is readily available for reference.

One of the key advantages of historical data storage in mechanical databases is the ability to track changes over time. Engineers can compare current performance data with historical records to assess the evolution of mechanical systems. This longitudinal analysis is crucial for identifying trends, evaluating the effectiveness of maintenance strategies, and making informed decisions about system upgrades or replacements.

Retrieving historical data from databases is a streamlined process that leverages query languages and data retrieval techniques. Engineers can specify criteria to extract specific sets of data, enabling them to focus on relevant information for analysis. This targeted retrieval is particularly beneficial for troubleshooting, predictive maintenance, and research purposes.

Databases also play a vital role in ensuring data integrity and security. By implementing robust data management practices, engineers can protect historical data from corruption, loss, or unauthorized access. Data redundancy and backup systems further contribute to the preservation of historical records, safeguarding critical information for future reference.

The integration of cloud-based solutions has revolutionized historical data storage and retrieval. Cloud databases offer scalability, accessibility, and collaborative features that enhance the efficiency of managing and analyzing historical data. Engineers can access data remotely, collaborate on analysis projects, and benefit from the computational power of cloud-based resources.

Moreover, historical data storage in databases is not limited to operational data alone. It also includes metadata, providing essential information about the context, source, and format of the stored data. This metadata enhances the interpretability and usability of historical data, ensuring that engineers can make informed decisions based on a comprehensive understanding of the data’s origin and characteristics.

Historical data storage and retrieval in databases are fundamental components of effective data management in mechanical systems. Well-organized databases support analysis, decision-making, and research activities, contributing to the continuous improvement and optimization of mechanical systems throughout their lifecycle.

Importance of Historical Data in Reliability Analysis

The importance of historical data in reliability analysis cannot be overstated when it comes to ensuring the dependability and performance of mechanical systems. Reliability analysis aims to assess the likelihood of a system or component functioning without failure over a specified period. Historical data serves as a treasure trove of information, offering insights into the past performance, failure modes, and maintenance history of mechanical systems. Leveraging this data is crucial for making informed decisions, predicting future behavior, and implementing effective strategies to enhance reliability.

One key aspect of using historical data in reliability analysis is the identification of failure patterns. By analyzing past failures and the circumstances leading up to them, engineers can discern patterns and trends that may indicate common failure modes. This knowledge is instrumental in implementing preventive measures to address potential issues before they escalate, thus improving the overall reliability of mechanical systems.

Moreover, historical data provides a basis for developing reliability models. Engineers can use statistical methods and probabilistic models to analyze the data and estimate the reliability metrics of mechanical components or systems. These models allow for predicting future reliability, setting maintenance schedules, and optimizing resource allocation to ensure maximum operational uptime.

Understanding the historical performance of a system also enables engineers to establish baseline reliability metrics. This baseline serves as a reference point for assessing the effectiveness of reliability improvement initiatives. By comparing current performance with historical data, engineers can measure the impact of interventions and adjustments, allowing for continuous refinement and optimization of reliability strategies.

The use of historical data is particularly crucial in industries where safety and reliability are paramount, such as aerospace, energy, and healthcare. In aviation, for example, analyzing the historical performance of aircraft components helps identify potential areas of concern and implement maintenance practices that ensure the safety of passengers and crew.

Historical data is a cornerstone of reliability analysis in mechanical systems. It provides valuable insights into failure patterns, facilitates the development of reliability models, establishes baseline metrics, and supports decision-making for optimizing system reliability. Harnessing the power of historical data is essential for enhancing the performance, safety, and dependability of mechanical systems.

Historical Data Visualization Tools for Mechanical Applications

Historical data visualization tools for mechanical applications play a pivotal role in transforming complex datasets into actionable insights. As the volume and complexity of historical data continue to grow, visualization tools become essential for engineers and decision-makers to interpret information, identify trends, and make informed choices. These tools facilitate a more intuitive understanding of historical data, leading to improved decision-making, system optimization, and innovation in mechanical applications.

One of the primary benefits of historical data visualization tools is the ability to present large datasets in a comprehensible format. Through charts, graphs, heatmaps, and other visual representations, engineers can quickly grasp trends, patterns, and anomalies in historical data. This visual clarity enhances the efficiency of analysis, enabling users to identify key insights and make data-driven decisions with greater confidence.

Time-series visualizations are particularly valuable in mechanical applications, allowing engineers to observe changes in performance, system behavior, or maintenance patterns over time. Trend lines, scatter plots, and animated graphs can illustrate the evolution of mechanical systems, aiding in the identification of long-term patterns or sudden deviations from established norms.

Furthermore, 3D visualization tools offer a new dimension to historical data analysis in mechanical applications. By representing data in three-dimensional space, engineers can gain a more comprehensive understanding of complex relationships and interactions within a system. This type of visualization is especially beneficial for analyzing spatial data, such as temperature distributions, stress patterns, or fluid dynamics in mechanical components.

Interactive visualization tools add another layer of functionality, allowing users to explore historical data dynamically. Engineers can zoom in on specific time periods, filter data based on parameters of interest, and interact with visual elements to gain deeper insights. This interactivity promotes a more engaged and exploratory approach to data analysis, empowering users to uncover hidden patterns or correlations.

The integration of historical data visualization tools with real-time monitoring systems enhances the capabilities of engineers to monitor and control mechanical systems effectively. Dashboards with live visualizations enable real-time decision-making and quick responses to emerging issues. This synergy between historical data analysis and real-time visualization is particularly valuable in industries where rapid response and proactive maintenance are critical.

Historical data visualization tools are indispensable for extracting meaningful insights from complex datasets in mechanical applications. These tools provide a visual context that enhances understanding, supports decision-making, and fosters innovation. As technology continues to advance, the development and adoption of sophisticated historical data visualization tools will play a vital role in optimizing the performance and reliability of mechanical systems.

Case Studies on Leveraging Historical Data for System Improvement

Case studies on leveraging historical data for system improvement showcase real-world examples of how organizations and engineers have utilized past data to enhance the performance, reliability, and efficiency of mechanical systems. These studies provide valuable insights into successful strategies, challenges faced, and the impact of historical data-driven decision-making on overall system improvement.

One illustrative case study involves a manufacturing facility that implemented a predictive maintenance program based on historical data analysis. By collecting and analyzing data from equipment sensors and maintenance records, the facility identified patterns indicative of impending failures. This proactive approach allowed the facility to schedule maintenance activities before critical components failed, resulting in a significant reduction in unplanned downtime and maintenance costs.

In the aerospace industry, a case study demonstrated the use of historical data to optimize aircraft maintenance schedules. By analyzing the performance and maintenance records of a fleet of aircraft, engineers identified patterns related to component lifespan and wear. This analysis led to the adjustment of maintenance intervals, ensuring that components were replaced or serviced at optimal times, improving overall reliability and reducing operational costs.

Another notable case study involves the energy sector, where historical data analysis was employed to optimize the performance of a power generation plant. By studying historical data on equipment efficiency, fuel consumption, and maintenance practices, engineers identified areas for improvement. Adjustments to operational parameters and maintenance schedules resulted in increased efficiency, reduced fuel consumption, and extended equipment lifespan.

In the field of healthcare, a case study highlighted the use of historical data to enhance the reliability of medical devices. By analyzing historical performance data and maintenance records, a hospital was able to identify potential issues with critical medical equipment before they became critical. This proactive approach not only improved patient safety but also resulted in cost savings through optimized maintenance practices.

These case studies underscore the diverse applications of leveraging historical data for system improvement across various industries. The common thread among these examples is the ability of historical data analysis to provide actionable insights, inform decision-making, and drive continuous improvement in mechanical systems.

Case studies on leveraging historical data for system improvement serve as valuable references for organizations and engineers seeking to enhance the performance, reliability, and efficiency of mechanical systems. These real-world examples demonstrate the tangible benefits of historical data-driven decision-making and offer inspiration for the adoption of similar strategies in diverse industrial contexts.