Relational vs. NoSQL Databases for Mechanical Applications

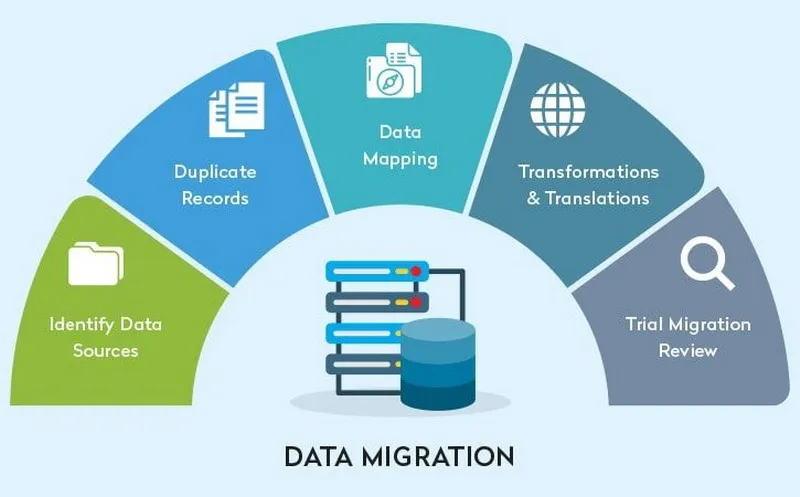

Choosing between relational (SQL) and NoSQL databases for mechanical applications involves considering several factors to ensure an optimal fit for the specific needs of the application.

Relational databases are well-suited for mechanical applications that deal with structured and tabular data. These databases enforce a predefined schema, ensuring data integrity and consistency through ACID properties. If the application requires complex queries, relationships between different entities, and transaction support—common in scenarios such as managing bills of materials or tracking product lifecycle stages—relational databases like MySQL or PostgreSQL may be a solid choice.

On the other hand, NoSQL databases offer advantages in scenarios where data structures are evolving or not well-defined. Mechanical applications that involve varying data formats or where adaptability to changing requirements is crucial can benefit from the flexible schema of NoSQL databases like MongoDB or Cassandra. Additionally, NoSQL databases often excel in scalability, handling large volumes of unstructured or semi-structured data efficiently. This scalability is valuable in applications dealing with sensor data, simulations, or other data-intensive tasks.

Ultimately, the choice between relational and NoSQL databases for mechanical applications depends on factors such as data structure, scalability needs, and the nature of queries and transactions the application demands. Hybrid approaches, combining the strengths of both types of databases, can also be considered for applications with diverse data management requirements.

Relational vs. NoSQL Databases for Mechanical Applications

The choice between relational and NoSQL databases in the context of mechanical applications involves evaluating the specific requirements and characteristics of the data and the system’s use cases. Relational databases have long been the conventional choice, offering structured and normalized data storage, while NoSQL databases provide flexibility and scalability, particularly beneficial for handling unstructured or rapidly changing data. Let’s explore the considerations and factors that influence the decision between these two types of databases in the realm of mechanical applications.

Relational Databases:

Relational databases, represented by popular systems like MySQL, PostgreSQL, and Microsoft SQL Server, organize data into structured tables with predefined schemas. In mechanical applications, where data often adheres to a well-defined structure such as parts specifications, engineering drawings, and assembly hierarchies, relational databases have historically been a natural fit.

Advantages:

- Data Integrity: Relational databases enforce data integrity through mechanisms such as primary and foreign key constraints, ensuring that relationships between different pieces of data are maintained.

- ACID Compliance: Relational databases follow the ACID (Atomicity, Consistency, Isolation, Durability) properties, providing strong transactional guarantees, which is critical for applications where data consistency is paramount.

- Structured Query Language (SQL): The standardized SQL language simplifies data retrieval, manipulation, and analysis. It is well-suited for complex queries and reporting in scenarios where structured data is predominant.

Considerations:

- Schema Rigidity: While the structured nature of relational databases ensures data consistency, it can also introduce rigidity. Changes to the schema, such as adding new fields, may require downtime and careful migration strategies.

NoSQL Databases:

NoSQL databases, including MongoDB, Cassandra, and Redis, adopt a more flexible approach to data storage, accommodating various data formats and evolving schemas. In the context of mechanical applications, where data may exhibit variability in structure or experience rapid changes, NoSQL databases offer advantages in terms of scalability and adaptability.

Advantages:

- Schema Flexibility: NoSQL databases allow for dynamic and schema-less data structures, enabling easy adaptation to changing data requirements without the need for a predefined schema.

- Scalability: NoSQL databases excel in horizontal scalability, making them suitable for applications with growing datasets or distributed architectures. This is beneficial for handling large volumes of sensor data, simulations, or IoT-generated information common in mechanical systems.

- Performance: NoSQL databases can offer superior performance for specific use cases, such as real-time data processing and retrieval. This can be advantageous in scenarios where rapid access to diverse data types is essential.

Considerations:

- Consistency Models: NoSQL databases may follow eventual consistency models rather than the strict consistency of relational databases. Depending on the application requirements, this can introduce trade-offs in terms of data consistency guarantees.

- Learning Curve: Transitioning from the familiar SQL language to NoSQL query languages or APIs might pose a learning curve for developers accustomed to relational databases.

- Use Case Suitability: NoSQL databases are well-suited for scenarios with dynamic and unstructured data. However, they may not be the optimal choice for applications where complex transactions and relationships are predominant.

Comparison of Relational Databases in Mechanical Systems

In the realm of mechanical systems, relational databases play a significant role in providing a structured and organized framework for storing and managing data. Whether it’s maintaining parts specifications, engineering drawings, or historical records, relational databases offer several advantages in the context of mechanical applications.

Advantages:

- Structured Data Storage: Relational databases excel at organizing data into structured tables with well-defined relationships. In mechanical systems, where data often follows a rigid structure, this approach ensures consistency and integrity.

- Data Integrity: Relational databases enforce data integrity through features like primary keys, foreign keys, and constraints. This ensures that relationships between different pieces of data are maintained, preventing inconsistencies.

- ACID Compliance: The ACID properties (Atomicity, Consistency, Isolation, Durability) of relational databases provide strong transactional guarantees. This is crucial in mechanical applications where precise and consistent data representation is essential.

Considerations:

- Schema Rigidity: While the structured nature of relational databases ensures data integrity, it can introduce challenges when dealing with evolving data requirements. Modifications to the schema may require careful planning and, in some cases, downtime.

- Performance Trade-offs: In scenarios where complex queries are essential, relational databases may face performance trade-offs. Proper indexing and optimization strategies are necessary to maintain responsiveness, especially as the dataset grows.

Advantages of NoSQL Databases for Mechanical Data

NoSQL databases offer a compelling set of advantages for handling mechanical data, particularly in scenarios where data structures are dynamic, and scalability is a primary concern. The flexibility and adaptability of NoSQL databases make them well-suited for applications in mechanical systems that involve diverse and evolving data requirements.

Advantages:

- Schema Flexibility: NoSQL databases provide a schema-less approach, allowing for the storage of unstructured or semi-structured data. In mechanical applications, where data formats can vary or change over time, this flexibility is advantageous.

- Scalability: NoSQL databases excel in horizontal scalability, making them suitable for handling large volumes of data generated by sensors, simulations, or IoT devices commonly found in mechanical systems. The ability to scale horizontally ensures performance as data grows.

- Adaptability to Change: Mechanical systems often undergo changes in design, components, or data structure. NoSQL databases can easily adapt to these changes without requiring extensive modifications to predefined schemas, providing agility and reducing development overhead.

Considerations:

- Consistency Models: NoSQL databases may follow eventual consistency models rather than the strict consistency of relational databases. Depending on the specific mechanical application, this trade-off in data consistency may or may not be acceptable.

- Learning Curve: Transitioning from relational databases to NoSQL solutions might involve a learning curve for development teams. Familiarity with NoSQL query languages or APIs may need to be developed.

- Use Case Suitability: The advantages of NoSQL databases shine in scenarios where data is dynamic, unstructured, or requires rapid scalability. However, in applications where complex transactions and well-defined relationships are critical, a relational database might be a more suitable choice.

In conclusion, the choice between relational and NoSQL databases in mechanical applications hinges on the specific characteristics of the data, the application’s requirements, and considerations regarding scalability, flexibility, and consistency. Each type of database brings its unique strengths, and the decision should be informed by a careful analysis of the particular needs and challenges posed by the mechanical system at hand.

Use Cases for Relational Databases in Mechanical Engineering

Relational databases play a crucial role in various aspects of mechanical engineering, providing a structured and organized approach to data storage and management. The inherent features of relational databases, including the ability to enforce data integrity, maintain relationships between entities, and support complex queries, make them well-suited for a range of use cases within the field of mechanical engineering.

- Parts and Inventory Management: Relational databases excel in managing parts and inventory data. Mechanical engineering projects often involve a vast array of components with specific specifications. A relational database can organize this information in tables, linking parts to suppliers, specifications, and usage history. This ensures efficient tracking, ordering, and maintenance of parts.

- Design and Engineering Documents: In mechanical engineering, design specifications, engineering drawings, and documentation are paramount. Relational databases offer a structured framework to store and retrieve these documents. By creating relationships between projects, components, and associated documents, engineers can easily access the relevant information needed for design and analysis.

- Project Management: Managing complex projects in mechanical engineering requires tracking various aspects such as timelines, milestones, and resource allocation. Relational databases provide a robust solution for project management by organizing data related to project schedules, task assignments, and collaboration among team members.

- Quality Control and Testing: Relational databases are instrumental in quality control processes. By maintaining a structured database of testing parameters, results, and quality standards, mechanical engineers can ensure that products meet specified requirements. The relational model allows for the creation of normalized tables that represent different aspects of the testing process.

- Maintenance and Lifecycle Management: Mechanical systems undergo maintenance and have defined lifecycles. Relational databases facilitate the tracking of maintenance schedules, repair history, and lifecycle stages of equipment or machinery. This information aids in predictive maintenance, reducing downtime and extending the lifespan of assets.

- Simulation and Analysis Data: In the realm of mechanical engineering simulations and analyses, relational databases offer a systematic approach to storing simulation inputs, results, and iterative data. Engineers can use relational structures to establish connections between simulation runs, compare results, and make informed design decisions.

- Regulatory Compliance: Relational databases are well-suited for managing data related to regulatory compliance in mechanical engineering. Whether it involves adhering to industry standards or complying with environmental regulations, relational databases provide a reliable framework to store and retrieve compliance-related information.

In summary, the use cases for relational databases in mechanical engineering span various critical functions, from managing parts and projects to ensuring quality control and compliance. The structured nature of relational databases aligns well with the organized and interconnected nature of data in mechanical systems, making them a foundational technology in the field.

NoSQL Database Models for Industrial Applications

NoSQL databases offer diverse models that cater to specific needs, making them applicable to a wide range of industrial applications. In the context of industries such as manufacturing, energy, and logistics, where data is often dynamic, unstructured, and distributed, NoSQL databases provide flexible and scalable solutions. Let’s explore some of the prominent NoSQL database models and their use cases in industrial applications.

- Document-Oriented Databases (e.g., MongoDB): Document-oriented databases store data in flexible, JSON-like documents, allowing for nested structures and dynamic schemas. In industrial applications, these databases are beneficial for managing diverse data types, such as equipment specifications, sensor readings, and maintenance logs. The hierarchical structure accommodates complex relationships between different data elements.

- Key-Value Stores (e.g., Redis): Key-value stores excel in handling simple data structures where each piece of data is associated with a unique key. In industrial settings, key-value stores are suitable for scenarios requiring rapid data retrieval, such as real-time monitoring of equipment statuses, inventory management, and tracking sensor data. They offer high performance and scalability for read and write-intensive operations.

- Column-Family Stores (e.g., Apache Cassandra): Column-family stores organize data into columns rather than rows, making them efficient for time-series data and scalable across distributed architectures. In industrial applications, column-family databases are valuable for managing large datasets generated by sensors, IoT devices, and industrial control systems. They provide quick and efficient access to historical data for analysis and decision-making.

- Graph Databases (e.g., Neo4j): Graph databases model relationships between entities as nodes and edges, making them suitable for applications where understanding and querying complex relationships are essential. In industrial settings, graph databases can be used for supply chain optimization, network analysis of equipment dependencies, and modeling hierarchical structures within a manufacturing process.

- Wide-Column Stores (e.g., Apache HBase): Wide-column stores organize data in tables, similar to relational databases, but with a dynamic schema and distributed architecture. In industrial applications, wide-column stores are effective for managing data with evolving schemas, such as product specifications, where attributes can vary across different products or versions.

Scalability Considerations for Relational Databases in Mechanical Systems

Scalability is a critical factor in ensuring the performance and efficiency of databases, especially in the context of large and dynamic datasets typical in mechanical systems. While relational databases have been a traditional choice for their robust data integrity and structured query capabilities, scalability considerations become increasingly important as the volume of data grows. Here are key considerations for addressing scalability in relational databases within the domain of mechanical systems.

- Vertical Scaling: Vertical scaling involves increasing the resources of a single database server, such as adding more CPU, RAM, or storage capacity. While this approach can improve performance, it has limitations in terms of scalability. Mechanical systems with rapidly expanding datasets may outgrow the capabilities of a single, vertically scaled database server.

- Horizontal Scaling: Horizontal scaling, or sharding, involves distributing the database across multiple servers. Each server handles a portion of the dataset, allowing for improved performance and accommodating larger volumes of data. Sharding can be challenging in relational databases due to complex relationships and maintaining data integrity across distributed nodes.

- Indexing and Query Optimization: Efficient indexing is crucial for scalability in relational databases. Well-designed indexes improve query performance, but excessive indexing can impact write operations. In mechanical systems, where real-time data retrieval is essential, optimizing queries and striking a balance with indexing strategies becomes crucial for maintaining responsiveness.

- Partitioning: Partitioning involves dividing large tables into smaller, more manageable partitions based on certain criteria. This enhances both query performance and data management. In the context of mechanical systems, partitioning can be applied to tables containing time-series data or components, allowing for more efficient storage and retrieval.

- Caching Mechanisms: Implementing caching mechanisms can alleviate the load on the database by storing frequently accessed data in memory. This is particularly beneficial for read-intensive operations in mechanical systems where certain datasets may be accessed repeatedly. Caching can be employed to reduce latency and enhance overall system responsiveness.

- Data Archiving and Purging: For systems with historical data, implementing archiving and purging strategies becomes essential for maintaining optimal performance. Relocating older or less frequently accessed data to archival storage or purging obsolete records helps in keeping the active dataset manageable.

- Database Replication: Replication involves creating copies of the database on separate servers. While this enhances fault tolerance and read scalability, it introduces challenges in maintaining consistency across replicas. In mechanical systems, where real-time data accuracy is critical, careful consideration of replication strategies is necessary.

- Use of Cloud Services: Leveraging cloud-based database services can provide scalability benefits by allowing dynamic allocation of resources based on demand. Cloud providers offer scalable infrastructure, allowing mechanical systems to adapt to changing data volumes without the need for upfront hardware investments.

In conclusion, addressing scalability in relational databases within the context of mechanical systems requires a combination of architectural considerations, optimization strategies, and, in some cases, a shift towards more scalable database models. Balancing the structured nature of relational databases with the need for scalability is crucial for ensuring that these systems can handle the increasing complexity and volume of data inherent in mechanical engineering applications.