Database Schema Design for Mechanical Systems

Last Updated on January 4, 2024 by Mutiara

The foundation of efficient and effective data management in mechanical systems lies in the database schema design. A well-crafted database schema serves as the blueprint for organizing and structuring data, ensuring optimal performance, reliability, and ease of use. In the context of mechanical systems, where large volumes of diverse data are generated, database schema design plays a pivotal role in facilitating seamless operations and meaningful analysis.

Database Schema Design for Mechanical Systems

One of the key considerations in database schema design for mechanical systems is understanding the nature of the data being generated. Mechanical systems produce a wide array of data types, including sensor readings, maintenance logs, design specifications, and performance metrics. The schema must be designed to accommodate this diversity, providing a structured and organized framework for storing and retrieving information.

Normalization is a fundamental principle in database schema design, especially for mechanical systems where data integrity is paramount. By eliminating data redundancy and dependency, normalization reduces the risk of inconsistencies and improves the overall reliability of the database. This is particularly crucial in applications such as aerospace or automotive engineering, where precision and accuracy are non-negotiable.

Another consideration is the incorporation of relationships between different data entities. Mechanical systems involve interconnected components, and the database schema should reflect these relationships. Foreign key constraints and associations between tables ensure that the relationships are maintained, enabling comprehensive analysis and efficient retrieval of related information.

Furthermore, scalability is a critical factor in the design of database schemas for mechanical systems. As the volume of data grows or new components are introduced, the schema should be scalable to accommodate these changes without sacrificing performance. Well-defined indexes and partitioning strategies contribute to efficient query performance, even as the database scales.

Database schema design for mechanical systems is a meticulous process that requires a deep understanding of the data, adherence to normalization principles, consideration of relationships between entities, and a focus on scalability. A well-designed schema sets the stage for robust data management, facilitating seamless operations and empowering engineers and decision-makers to derive meaningful insights from the wealth of information generated by mechanical systems.

Database Schema Best Practices for Mechanical Applications

In the dynamic field of mechanical applications, adopting best practices for database schema design is essential to ensure optimal performance, maintainability, and adaptability. The complexity and diversity of data generated by mechanical systems demand a thoughtful approach to schema design that aligns with industry standards and facilitates efficient data management. Here are some key best practices for designing database schemas in mechanical applications:

- Understand Data Requirements: Thoroughly understand the types of data that will be stored in the database. This includes sensor data, maintenance logs, design specifications, and any other relevant information. This understanding forms the basis for designing an effective schema that meets the specific needs of the application.

- Normalization for Data Integrity: Embrace normalization principles to eliminate redundancy and dependency within the database. This not only improves data integrity but also reduces the likelihood of anomalies and inconsistencies. Mechanical applications often require precision, making normalization a crucial aspect of maintaining accurate and reliable data.

- Consider Relationships Between Entities: Mechanical systems comprise interconnected components. Design the schema to reflect these relationships by incorporating foreign keys and establishing associations between tables. This relational approach enables the representation of complex structures and facilitates comprehensive data analysis.

- Scalability for Growing Data Volumes: Anticipate the growth of data volumes over time and design the schema to be scalable. Employ strategies such as well-defined indexes and partitioning to ensure efficient query performance even as the database expands. Scalability is vital in mechanical applications where data generation rates can be substantial.

- Balance Normalization and Performance: While normalization is crucial for data integrity, strike a balance with performance considerations. In some cases, denormalization may be necessary to optimize query performance. Evaluate the trade-offs between normalization and denormalization based on specific performance requirements.

- Use Enumerations for Categorical Data: Mechanical systems often involve categorical data, such as equipment types or failure modes. Utilize enumerations to represent these categories within the schema. Enumerations enhance data consistency and provide an efficient way to manage and query categorical information.

- Implement Clear Naming Conventions: Establish clear and consistent naming conventions for tables, columns, and relationships. This practice enhances the maintainability of the schema and ensures that users can easily understand the structure of the database. Clarity in naming conventions simplifies collaboration among team members.

- Document the Schema Design: Document the database schema design comprehensively. Include details about the purpose of each table, the relationships between tables, and any specific constraints or considerations. A well-documented schema becomes a valuable resource for developers, administrators, and other stakeholders.

- Prioritize Data Security: Implement security measures within the schema to safeguard sensitive data. Utilize encryption, access controls, and authentication mechanisms to protect against unauthorized access. In mechanical applications, where proprietary designs and sensitive information may be stored, robust security is imperative.

- Regularly Review and Refine: Database schema design is not a one-time task; it should be an ongoing process. Regularly review the schema, especially when there are changes in data requirements or business processes. Refine the schema to accommodate evolving needs and ensure its alignment with the overall objectives of the mechanical application.

By adhering to these best practices, organizations can create robust and efficient database schemas for mechanical applications. These practices contribute to data integrity, scalability, and performance, ultimately enhancing the value derived from the wealth of data generated by modern mechanical systems.

Mechanical Data Modeling in Databases

Mechanical data modeling in databases involves the systematic representation of data generated by mechanical systems, facilitating efficient storage, retrieval, and analysis. In the realm of mechanical engineering, where precise modeling is crucial for designing and maintaining systems, the database schema must accurately capture the intricacies of mechanical data. Here, we explore the key considerations and methodologies involved in mechanical data modeling.

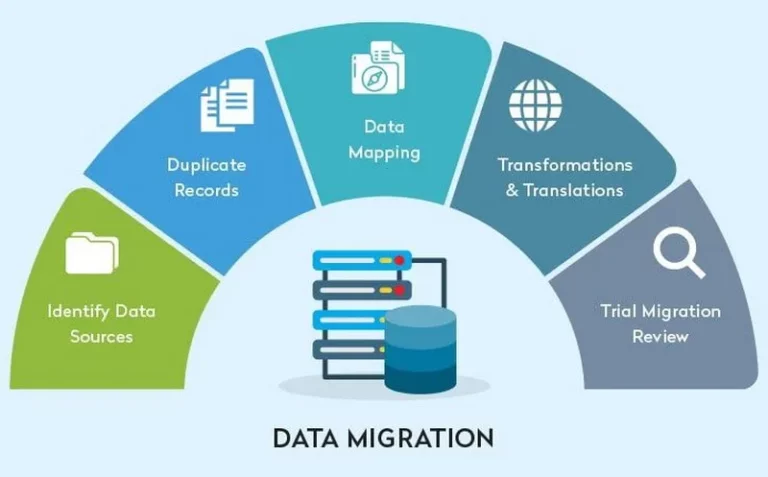

- Identify Data Entities: Begin the data modeling process by identifying the primary entities within the mechanical system. These entities can include components, sensors, maintenance records, design specifications, and any other relevant data sources. This step lays the foundation for organizing the data in a structured manner.

- Define Attributes for Each Entity: For each identified entity, define the attributes that characterize it. Attributes represent the specific properties or characteristics of the entity. For example, a sensor entity may have attributes such as sensor ID, type, location, and timestamp. This level of granularity ensures that the database accurately captures the details of each data point.

- Establish Relationships Between Entities: Mechanical systems are inherently interconnected, and the relationships between different entities must be clearly defined. Use relationship modeling to establish connections between entities. For instance, a maintenance record entity may be linked to a specific component entity, indicating the relationship between maintenance activities and the components they affect.

- Utilize Entity-Relationship Diagrams (ERDs): Visualize the relationships and structure of the database using Entity-Relationship Diagrams (ERDs). ERDs provide a graphical representation of entities, attributes, and relationships, offering a clear and intuitive view of the database schema. This visual representation is instrumental in communicating the data model to stakeholders.

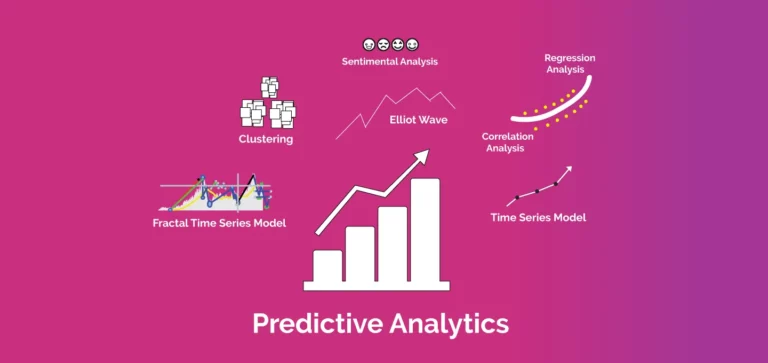

- Consider Temporal Aspects: Mechanical data often has temporal aspects, such as timestamps for sensor readings or maintenance events. Incorporate temporal considerations into the data model to accurately represent the timeline of events. This enables organizations to analyze data trends over time and make informed decisions based on historical information.

- Handle Heterogeneous Data: Mechanical systems generate diverse data types, including numerical sensor readings, textual maintenance logs, and graphical design specifications. Design the database schema to handle heterogeneous data efficiently. This may involve using appropriate data types and structures to accommodate different forms of information.

- Address Data Versioning: In mechanical applications, designs and specifications may evolve over time. Implement data versioning mechanisms within the data model to track changes and maintain a historical record of design iterations. This ensures that the database reflects the evolution of mechanical components and systems.

- Optimize for Performance: Consider performance optimization in the data model, especially for large datasets common in mechanical applications. Employ indexing, partitioning, and other performance-enhancing techniques to ensure efficient query execution and data retrieval.

- Facilitate Data Retrieval with Views: Create views within the data model to facilitate easier data retrieval for specific purposes. Views act as virtual tables that present a subset of data or transform the data in a way that meets specific querying or reporting requirements. This enhances the flexibility and usability of the database.

- Adhere to Database Standards: Follow established database standards and best practices during the data modeling process. This includes adhering to normalization principles, using appropriate naming conventions, and ensuring that the model aligns with the overall database architecture.

Schema Design Tools for Mechanical Databases

Effective schema design is crucial for optimizing the management of data in mechanical databases, and several tools are available to facilitate this process. These tools are designed to assist engineers, database administrators, and data architects in creating well-structured, efficient, and scalable database schemas for mechanical systems. Here are some schema design tools commonly used in the context of mechanical databases:

- MySQL Workbench: MySQL Workbench is a visual database design tool that supports the creation, modification, and documentation of database schemas. With a user-friendly interface, it allows designers to visually model the structure of a database, including tables, relationships, and indexes. It is particularly useful for mechanical databases that leverage MySQL as their underlying database management system.

- ER/Studio: ER/Studio is a comprehensive data modeling tool that supports both logical and physical database design. It provides a visual environment for designing and documenting database schemas, making it easier to collaborate and communicate the structure of mechanical databases. ER/Studio offers features for forward and reverse engineering, ensuring consistency between the visual model and the actual database implementation.

- Microsoft Visio: Microsoft Visio, although not exclusively designed for database modeling, offers templates and shapes for creating entity-relationship diagrams (ERDs). It is a versatile tool that can be used for visualizing and documenting the structure of mechanical databases. Visio integrates well with other Microsoft products, making it suitable for organizations using Microsoft SQL Server or Azure databases.

- dbForge Studio: dbForge Studio is a database development and management tool that includes a visual designer for creating and modifying database schemas. It supports various database systems, including Oracle, SQL Server, and MySQL. The visual designer in dbForge Studio allows users to define tables, relationships, and other schema elements for mechanical databases efficiently.

- Navicat Data Modeler: Navicat Data Modeler is a powerful and user-friendly tool for database design. It supports a wide range of database systems, making it suitable for diverse mechanical applications. With features like diagram synchronization and model generation, Navicat Data Modeler streamlines the process of designing and maintaining complex database schemas.

- Oracle SQL Developer Data Modeler: Oracle SQL Developer Data Modeler is a free data modeling tool provided by Oracle. It offers a graphical interface for designing, documenting, and deploying database schemas. This tool is well-suited for mechanical databases that utilize Oracle Database. It supports both relational and multidimensional data models.

- IBM Data Architect: IBM Data Architect is an enterprise-level data modeling tool that enables users to design and visualize database schemas. It supports various database management systems and offers collaborative features for team-based schema design. IBM Data Architect is suitable for large-scale mechanical systems where collaboration and scalability are critical.

- Lucidchart: Lucidchart is a cloud-based diagramming tool that includes features for creating entity-relationship diagrams (ERDs) and other visual representations of database schemas. It is accessible from any device with an internet connection, making it convenient for collaborative design efforts. Lucidchart is suitable for mechanical databases where distributed teams may be involved in the design process.

In conclusion, schema design tools play a crucial role in the development of well-organized and efficient database structures for mechanical systems. The choice of a specific tool depends on factors such as the database management system being used, the preferences of the design team, and the need for collaboration. These tools streamline the process of creating, modifying, and documenting database schemas, ultimately contributing to the effective management of data in mechanical applications.

Importance of Database Normalization in Mechanical Systems

Database normalization is a fundamental concept in database design that holds particular significance in the context of mechanical systems. Normalization is the process of organizing and structuring data in a database to eliminate redundancy and dependency, leading to improved data integrity and efficiency. In the realm of mechanical systems, where precision and accuracy are paramount, the importance of database normalization cannot be overstated.

Here are key reasons why database normalization is crucial in the context of mechanical systems:

- Elimination of Data Redundancy: Mechanical systems generate vast amounts of data, ranging from sensor readings to maintenance logs. Normalization helps eliminate data redundancy by organizing data into separate tables and ensuring that each piece of information is stored in one place. This not only conserves storage space but also prevents inconsistencies that can arise from duplicate data.

- Maintenance of Data Integrity: Mechanical databases often involve complex relationships between different components and subsystems. Normalization prevents update anomalies, insertion anomalies, and deletion anomalies that can compromise data integrity. By breaking down data into smaller, related tables, normalization ensures that modifications to the database maintain the accuracy and consistency of the information.

- Optimization of Query Performance: In mechanical systems, where real-time monitoring and quick decision-making are critical, query performance is essential. Normalized databases are typically more efficient when it comes to querying specific pieces of information. Well-defined relationships between tables allow for faster retrieval of relevant data without the need to sift through redundant or irrelevant information.

- Scalability and Flexibility: Mechanical systems are dynamic, and the data requirements may evolve over time. Normalization provides a foundation for scalable database structures. As new components are added or data types change, the normalized schema can adapt more easily to these modifications without disrupting the existing structure. This flexibility is essential for accommodating the changing needs of mechanical applications.

- Simplified Updates and Modifications: When updates or modifications to the database schema are necessary, normalization simplifies the process. Changes can be made to a specific table without affecting other parts of the database. This modular approach makes it easier for database administrators to manage and maintain the database schema in response to evolving requirements.

- Consistent Data Modeling: Normalization enforces a consistent approach to data modeling. By adhering to normalization principles, database designers ensure that similar types of data are treated consistently across the database. This consistency enhances the understandability of the database schema, making it easier for engineers, analysts, and decision-makers to work with the data.

- Reduction of Update Anomalies: Update anomalies occur when changes to data result in inconsistencies. Normalization helps minimize these anomalies by breaking down tables into smaller, related entities. This ensures that updates are applied uniformly and do not lead to discrepancies in the database.

- Enhanced Data Security: Normalization contributes to data security by reducing the risk of unauthorized access to sensitive information. By organizing data efficiently, normalization ensures that only authorized users can access specific parts of the database, enhancing overall security in mechanical systems where proprietary designs and confidential information may be stored.

In conclusion, the importance of database normalization in mechanical systems lies in its ability to eliminate data redundancy, maintain data integrity, optimize query performance, facilitate scalability, simplify updates, ensure consistent data modeling, reduce update anomalies, and enhance data security. These benefits collectively contribute to the reliability, efficiency, and adaptability of database structures in the complex and dynamic environment of mechanical applications.

Database Schema Examples for Engineering Applications

Database schema examples for engineering applications serve as blueprints for organizing and structuring data in a way that supports efficient data management, retrieval, and analysis. In engineering contexts, such as mechanical and civil engineering, where intricate relationships and precise data are prevalent, the design of a well-crafted database schema is essential. Here are two illustrative examples of database schemas tailored for engineering applications:

- Asset Management Database Schema:

Entities:

- Assets: Stores information about mechanical components, equipment, or structures.

- Maintenance Records: Captures details of maintenance activities performed on assets.

- Sensors: Represents data from sensors monitoring asset conditions.

Attributes:

- Assets:

- Asset_ID (Primary Key)

- Asset_Name

- Installation_Date

- Manufacturer

- Model

- …

- Maintenance Records:

- Maintenance_ID (Primary Key)

- Asset_ID (Foreign Key)

- Maintenance_Date

- Technician

- Description

- …

- Sensors:

- Sensor_ID (Primary Key)

- Asset_ID (Foreign Key)

- Sensor_Type

- Location

- Reading

- Timestamp

- …

Relationships:

- One-to-Many relationship between Assets and Maintenance Records (One asset can have multiple maintenance records).

- One-to-Many relationship between Assets and Sensors (One asset can have multiple sensors).

- Project Management Database Schema:

Entities:

- Projects: Stores information about engineering projects.

- Tasks: Represents individual tasks or activities within a project.

- Team Members: Captures details of team members involved in projects.

Attributes:

- Projects:

- Project_ID (Primary Key)

- Project_Name

- Start_Date

- End_Date

- Project_Manager

- …

- Tasks:

- Task_ID (Primary Key)

- Project_ID (Foreign Key)

- Task_Name

- Description

- Status

- Deadline

- …

- Team Members:

- Member_ID (Primary Key)

- Project_ID (Foreign Key)

- Member_Name

- Role

- …

Relationships:

- One-to-Many relationship between Projects and Tasks (One project can have multiple tasks).

- One-to-Many relationship between Projects and Team Members (One project can have multiple team members).

These examples demonstrate the versatility of database schemas in engineering applications. In the asset management schema, the focus is on capturing data related to assets, maintenance records, and sensor readings. In the project management schema, the emphasis is on organizing information about projects, tasks, and team members. Both schemas leverage relationships and normalization to ensure data accuracy, consistency, and efficient querying. These examples serve as starting points for designing tailored database schemas that meet the specific requirements of engineering projects and facilitate seamless data management.

In conclusion, mechanical data modeling in databases is a meticulous process that involves identifying entities, defining attributes, establishing relationships, visualizing the schema with ERDs, considering temporal aspects, handling heterogeneous data, addressing data versioning, optimizing for performance, facilitating data retrieval with views, and adhering to database standards. A well-designed data model serves as the backbone of efficient data management in mechanical systems, enabling organizations to harness the full potential of the data generated by modern engineering processes.