Predictive Maintenance Using Database Analytics

Predictive maintenance has become a cornerstone of modern asset management, leveraging advanced technologies to anticipate and address equipment failures before they occur. In the realm of database management, predictive maintenance using database analytics plays a pivotal role in ensuring the reliability and performance of critical systems. This approach involves the application of advanced analytics and machine learning to database-related data, enabling organizations to proactively identify potential issues, optimize performance, and minimize downtime.

Predictive Maintenance Using Database Analytics

The key components and processes involved in predictive maintenance using database analytics include:

- Data Collection and Monitoring: Predictive maintenance begins with the continuous collection of data from various sources within the database environment. This includes performance metrics, usage patterns, error logs, and other relevant parameters. Monitoring tools track the health and behavior of the database in real time, creating a comprehensive dataset for analysis.

- Data Preprocessing and Cleaning: Raw data collected from databases often requires preprocessing to ensure accuracy and relevance. This step involves cleaning the data, handling missing values, and transforming it into a suitable format for analysis. Clean and well-organized data is essential for the effectiveness of predictive maintenance algorithms.

- Feature Extraction and Selection: Database analytics involves identifying key features or variables that can be indicative of the system’s health. Feature extraction and selection aim to highlight the most relevant data points for analysis. These features serve as inputs for predictive models, providing valuable information about the state of the database.

- Algorithm Selection and Training: Predictive maintenance algorithms for databases vary in complexity and suitability for different scenarios. Machine learning algorithms, such as regression, decision trees, or neural networks, are trained using historical data to learn patterns and relationships. The choice of algorithm depends on the nature of the database, the available data, and the specific goals of the predictive maintenance strategy.

- Model Validation and Testing: The trained predictive maintenance model needs to be validated and tested to ensure its accuracy and reliability. This involves assessing the model’s performance on a separate dataset not used during the training phase. Rigorous testing helps identify potential issues and fine-tune the model for optimal performance.

- Deployment and Integration: Once validated, the predictive maintenance model is deployed and integrated into the database management system. It operates in real time, continuously analyzing incoming data and generating predictions or alerts regarding potential issues. Integration with existing database infrastructure ensures seamless operation and minimal disruption.

- Alerts and Notifications: Predictive maintenance using database analytics is designed to be proactive. When the model identifies anomalies or potential failures, it generates alerts or notifications. These alerts are then communicated to relevant stakeholders, such as database administrators or maintenance teams, enabling timely intervention before issues escalate.

- Continuous Improvement and Iteration: Predictive maintenance is an evolving process. Continuous monitoring of the model’s performance allows for iterative improvements. As the database environment changes or new patterns emerge, the predictive maintenance algorithms can be updated to maintain effectiveness and accuracy over time.

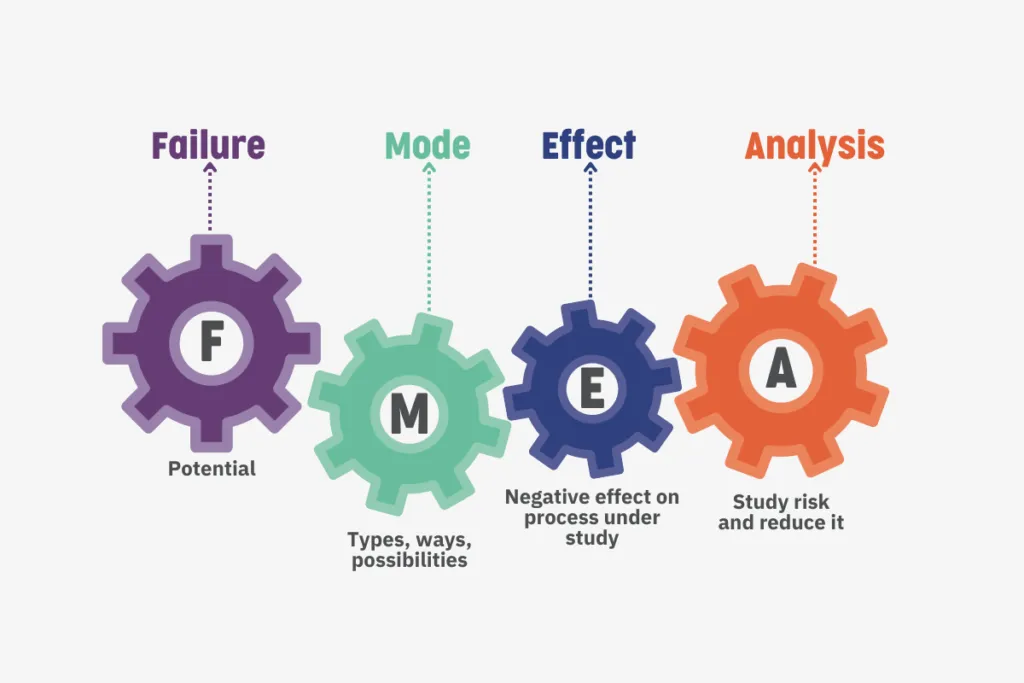

Predictive Maintenance Algorithms for Databases

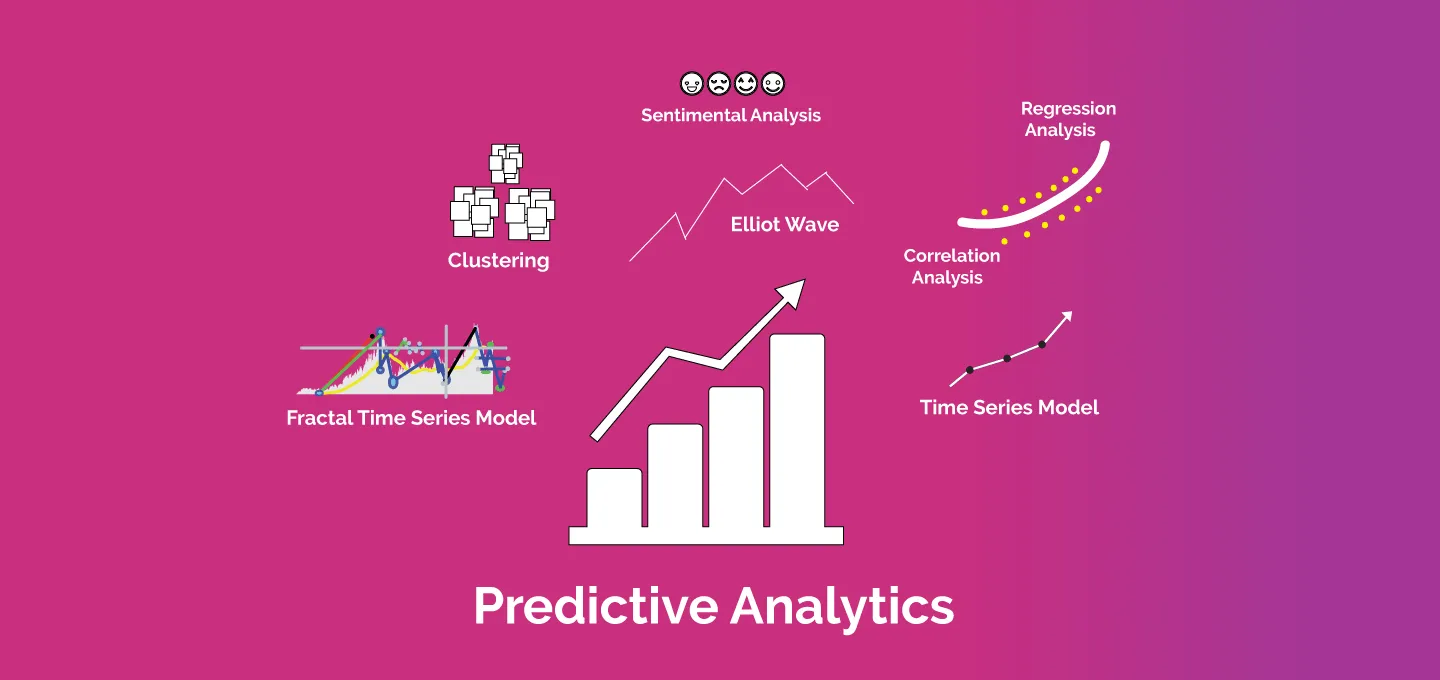

Predictive maintenance algorithms for databases leverage machine learning and statistical techniques to analyze historical and real-time data, enabling the prediction of potential issues and failures. These algorithms play a crucial role in optimizing the performance and reliability of database systems. Here are some common predictive maintenance algorithms employed in the database context:

- Regression Analysis: Regression algorithms analyze the relationship between dependent and independent variables to predict the values of the dependent variable. In the context of predictive maintenance for databases, regression models can be used to predict performance metrics, identify trends, and forecast potential issues based on historical data.

- Decision Trees: Decision tree algorithms use a tree-like model of decisions and their possible consequences. In predictive maintenance, decision trees can be employed to analyze various factors influencing database health and make predictions about future states. Decision trees are interpretable and can be useful for understanding the key factors leading to potential issues.

- Random Forests: Random Forests are an ensemble learning technique that combines multiple decision trees to improve predictive accuracy and robustness. In the context of database analytics, Random Forests can handle complex relationships within the data, providing a more comprehensive understanding of potential failure scenarios.

- Support Vector Machines (SVM): SVM is a supervised learning algorithm that can be used for classification and regression tasks. In predictive maintenance for databases, SVM can be applied to classify database states as normal or anomalous, helping detect deviations from expected behavior and predicting potential issues.

- Neural Networks: Neural networks, particularly deep learning models, have shown significant success in predictive maintenance applications. These models can learn complex patterns and relationships within large datasets. In the context of databases, neural networks can analyze historical and real-time data to predict future states and potential failures.

- Time Series Analysis: Time series analysis focuses on patterns within sequential data points, making it particularly relevant for predictive maintenance in databases where events unfold over time. Time series algorithms can identify trends, seasonality, and anomalies, helping predict future states based on historical patterns.

- Clustering Algorithms: Clustering algorithms, such as k-means or hierarchical clustering, can be applied to group similar database behavior patterns. By identifying clusters of normal and anomalous behavior, these algorithms contribute to predicting potential issues and understanding variations within the database environment.

- Anomaly Detection: Anomaly detection algorithms aim to identify instances that deviate significantly from normal patterns. In predictive maintenance for databases, anomaly detection can pinpoint unusual behavior or unexpected changes, indicating potential issues that may require attention.

The selection of a predictive maintenance algorithm depends on factors such as the complexity of the database environment, the nature of the data, and the specific goals of the maintenance strategy. It is common to use a combination of algorithms or an ensemble approach to achieve the best results.

Database Analytics for Equipment Health Prediction

Database analytics for equipment health prediction involves leveraging data-driven insights to anticipate the condition, performance, and potential failures of physical assets. In the context of industrial equipment, the integration of database analytics enables organizations to move from reactive to proactive maintenance strategies. By analyzing data collected from equipment sensors and databases, organizations can predict equipment health, optimize maintenance schedules, and minimize unplanned downtime. Here are key aspects of database analytics for equipment health prediction:

- Data Integration and Connectivity: Database analytics for equipment health prediction begins with the integration of data from various sources. This includes data from sensors embedded in equipment, historical maintenance records, and other relevant databases. Establishing seamless connectivity ensures that the analytics platform has access to a comprehensive dataset for analysis.

- Feature Engineering and Selection: Feature engineering involves transforming raw data into meaningful features that provide insights into equipment health. This process may include extracting relevant variables, creating derived features, and selecting the most informative parameters for analysis. Feature selection ensures that the analytics model focuses on the most impactful factors.

- Pattern Recognition and Anomaly Detection: Database analytics algorithms analyze patterns within the data to identify normal operating conditions and deviations indicative of potential issues. Anomaly detection techniques highlight unusual behavior or outliers that may be early indicators of equipment health problems. These patterns can be identified through statistical analysis, machine learning algorithms, or a combination of both.

- Predictive Modeling: Predictive modeling involves the development and training of algorithms to forecast equipment health based on historical and real-time data. These models can predict the remaining useful life of components, estimate the likelihood of failures, and provide actionable insights for maintenance planning. Common modeling techniques include regression, machine learning algorithms, and time series analysis.

- Real-Time Monitoring and Alerts: Database analytics for equipment health prediction operates in real time, continuously monitoring incoming data to assess the current state of equipment. When potential issues are identified, the analytics platform generates alerts or notifications. These alerts prompt maintenance teams to take preventive actions, reducing the risk of unexpected failures.

- Integration with Maintenance Management Systems: To maximize the impact of equipment health predictions, database analytics must seamlessly integrate with maintenance management systems. This integration ensures that predictions translate into actionable maintenance plans, work orders, and scheduling. By aligning analytics with maintenance workflows, organizations can optimize resource allocation and minimize downtime.

- Continuous Improvement and Adaptability: The field of equipment health prediction is dynamic, and the analytics model must adapt to changing conditions. Continuous improvement involves regularly updating the predictive model based on new data and feedback. This adaptability ensures that the analytics platform remains effective in addressing evolving equipment health challenges.

- Root Cause Analysis: In the event of equipment failures, database analytics can contribute to root cause analysis by examining historical data leading up to the failure. This retrospective analysis helps identify the factors that contributed to the failure, informing future predictive models and improving overall equipment reliability.

- Scalability for Large Datasets: Organizations managing extensive equipment fleets generate large volumes of data. Database analytics for equipment health prediction must be scalable to handle these large datasets efficiently. Scalability ensures that the analytics platform remains effective as the organization expands its infrastructure.

- Cost-Benefit Analysis: Implementing database analytics for equipment health prediction involves costs related to technology, training, and integration. Conducting a cost-benefit analysis helps organizations assess the return on investment by comparing the potential savings from avoided downtime and optimized maintenance to the expenses associated with analytics implementation.

Challenges in database analytics for equipment health prediction include data quality issues, the need for skilled data scientists and analysts, and the complexity of integrating analytics into existing workflows. Overcoming these challenges requires a strategic approach, collaboration between data and maintenance teams, and a commitment to continuous improvement.

Machine Learning for Predictive Maintenance

Machine learning (ML) has emerged as a powerful tool in the domain of predictive maintenance, revolutionizing how organizations manage their assets and infrastructure. Predictive maintenance using machine learning leverages advanced algorithms to analyze data from sensors, historical records, and other sources to forecast equipment failures and optimize maintenance schedules. This proactive approach minimizes downtime, reduces maintenance costs, and extends the lifespan of critical assets. Here’s an exploration of the key aspects of machine learning for predictive maintenance:

- Data Collection and Preprocessing: Machine learning for predictive maintenance begins with the collection of data from various sources, including sensors, IoT devices, and historical maintenance records. This raw data often requires preprocessing to handle missing values, clean outliers, and ensure uniformity. Quality data is crucial for training accurate machine learning models.

- Feature Engineering: Feature engineering involves selecting and transforming relevant variables (features) from the collected data. These features serve as inputs to machine learning algorithms and should capture key information about the health and performance of the equipment. Effective feature engineering enhances the model’s ability to identify patterns and make accurate predictions.

- Algorithm Selection: Choosing the right machine learning algorithm is critical for the success of predictive maintenance applications. Various algorithms, such as regression, decision trees, random forests, support vector machines, and neural networks, can be applied based on the nature of the data and the specific goals of the maintenance strategy. Ensemble methods, which combine multiple algorithms, are also commonly used for increased accuracy.

- Training and Validation: Machine learning models are trained using historical data that includes instances of both normal and failure conditions. The trained model is then validated using a separate dataset not used during the training phase. This validation ensures that the model can generalize well to new, unseen data, increasing its reliability in real-world scenarios.

- Real-Time Monitoring: Once trained and validated, machine learning models can operate in real time, continuously monitoring incoming data from sensors and other sources. The model assesses the current state of equipment health and provides predictions about potential failures. Real-time monitoring enables timely intervention and preventive maintenance.

- Anomaly Detection: Anomaly detection is a key aspect of machine learning for predictive maintenance. Machine learning models learn to recognize patterns of normal behavior and identify deviations indicative of potential issues. Anomalies may include unexpected fluctuations in sensor readings, irregularities in equipment performance, or other deviations from established norms.

- Predictive Modeling: Predictive maintenance models aim to forecast when equipment failures are likely to occur. These models analyze patterns within the data to predict the remaining useful life of components, estimate the likelihood of failures, and provide insights into the optimal timing for maintenance activities. Predictive modeling helps organizations plan maintenance activities proactively.

- Integration with Maintenance Workflows: Successful implementation of machine learning for predictive maintenance requires seamless integration with maintenance workflows. The insights generated by machine learning models need to translate into actionable maintenance plans, work orders, and scheduling. Integration ensures that the maintenance team can efficiently act on the predictions to optimize asset performance.

- Continuous Improvement: Machine learning models for predictive maintenance are not static; they evolve with time and new data. Continuous improvement involves updating models based on feedback, new observations, and changes in the operating environment. This iterative approach ensures that the models remain accurate and effective in dynamic conditions.

- Cost-Benefit Analysis: Implementing machine learning for predictive maintenance involves costs associated with data collection, model development, and integration. Conducting a cost-benefit analysis helps organizations assess the return on investment by comparing the potential savings from avoided downtime and optimized maintenance to the expenses associated with machine learning implementation.

Challenges in machine learning for predictive maintenance include the need for high-quality labeled data, interpretability of complex models, and addressing the “cold start” problem where sufficient failure data may be lacking initially. Overcoming these challenges requires collaboration between data scientists, domain experts, and maintenance professionals.

machine learning for predictive maintenance is a transformative approach that empowers organizations to move from reactive to proactive asset management. By harnessing the capabilities of advanced algorithms, organizations can optimize maintenance strategies, reduce costs, and ensure the reliability and longevity of critical assets.

Predictive Maintenance Case Studies in Databases

Predictive maintenance case studies in databases provide real-world examples of how organizations leverage advanced analytics and machine learning to optimize maintenance strategies, minimize downtime, and extend the lifespan of critical equipment. These case studies showcase the effectiveness of predictive maintenance in various industries, shedding light on the tangible benefits and outcomes. Let’s explore a few illustrative predictive maintenance case studies in databases:

- Aviation Industry: In the aviation industry, predictive maintenance plays a crucial role in ensuring the safety and reliability of aircraft. Airlines and maintenance providers use historical data, including sensor readings and maintenance records, to train machine learning models. These models can predict component failures, optimize maintenance schedules, and reduce unscheduled maintenance events. This proactive approach enhances operational efficiency and reduces disruptions in flight schedules.

- Manufacturing Sector: Manufacturing facilities rely heavily on machinery and equipment to maintain production schedules. Predictive maintenance in the manufacturing sector involves analyzing data from sensors embedded in machines to predict potential failures. By implementing machine learning models, manufacturers can optimize maintenance activities, reduce downtime, and prevent costly production interruptions. This approach leads to increased productivity and cost savings.

- Energy Infrastructure: In the energy sector, predictive maintenance is applied to critical infrastructure such as power plants and wind turbines. By analyzing data from sensors measuring equipment temperature, vibration, and other parameters, organizations can predict potential failures and schedule maintenance activities accordingly. This proactive approach minimizes unplanned downtime, increases the efficiency of energy production, and reduces operational costs.

- Railway Systems: Railway operators use predictive maintenance to ensure the reliability and safety of their rolling stock. By analyzing data from sensors on trains and tracks, machine learning models can predict issues such as wheel bearing failures, track irregularities, or other potential problems. This allows operators to schedule maintenance during non-peak hours, minimizing disruptions to passenger services and optimizing the overall performance of the railway network.

- Telecommunications Infrastructure: Telecommunications companies utilize predictive maintenance for their network infrastructure, including data centers and communication towers. By analyzing data from various sources, including equipment logs and performance metrics, machine learning models can predict equipment failures or degradation. This enables telecom providers to proactively address issues, reduce downtime, and ensure the continuous and reliable operation of their communication networks.

- Healthcare Equipment: Predictive maintenance is applied in the healthcare sector to ensure the reliability of critical medical equipment. Hospitals use machine learning models to analyze data from diagnostic machines, imaging equipment, and other medical devices. By predicting potential failures or maintenance needs, healthcare facilities can optimize equipment availability, improve patient care, and reduce the risk of unexpected breakdowns during critical medical procedures.

- Fleet Management: Predictive maintenance is widely employed in the management of vehicle fleets. Logistics companies, public transportation agencies, and delivery services use machine learning models to predict the maintenance needs of their vehicles. By analyzing data from vehicle sensors, odometer readings, and historical maintenance records, organizations can optimize maintenance schedules, reduce vehicle downtime, and enhance the overall efficiency of their fleets.

These predictive maintenance case studies highlight the versatility and impact of advanced analytics in optimizing asset management across diverse industries. By leveraging data-driven insights, organizations can transition from reactive to proactive maintenance strategies, resulting in improved operational efficiency, cost savings, and enhanced reliability.

Tools and Platforms for Predictive Maintenance Analytics

The successful implementation of predictive maintenance relies on robust tools and platforms that facilitate the analysis of data, development of machine learning models, and integration with existing maintenance workflows. A variety of tools and platforms have been developed to meet the specific needs of predictive maintenance analytics. Here’s an exploration of key tools and platforms in this domain:

- TensorFlow: TensorFlow, an open-source machine learning library developed by Google, is widely used for predictive maintenance analytics. It provides a flexible framework for building and deploying machine learning models. TensorFlow’s extensive ecosystem includes tools for data preprocessing, model training, and deployment, making it a popular choice for predictive maintenance applications.

- Microsoft Azure Machine Learning: Microsoft Azure offers a comprehensive machine learning platform that includes Azure Machine Learning. This platform provides tools for building, training, and deploying machine learning models at scale. Azure Machine Learning facilitates the integration of predictive maintenance models with other Azure services, enabling seamless deployment in cloud environments.

- IBM Watson Studio: IBM Watson Studio is an integrated environment for data science and machine learning. It provides tools for data preparation, model development, and collaboration among data science teams. Watson Studio supports the deployment of machine learning models, making it suitable for organizations implementing predictive maintenance analytics.

- Databricks: Databricks provides a unified analytics platform that integrates with popular big data frameworks such as Apache Spark. It offers collaborative tools for data engineering, data science, and machine learning. Databricks allows organizations to process large datasets efficiently and build predictive maintenance models on top of distributed computing environments.

- RapidMiner: RapidMiner is a data science platform that facilitates the end-to-end process of predictive maintenance analytics. It includes tools for data preparation, machine learning model development, and model deployment. RapidMiner’s visual interface is designed to be user-friendly, enabling data scientists and domain experts to collaborate effectively.

- MATLAB: MATLAB is a programming and modeling platform that is widely used in engineering and scientific applications, including predictive maintenance analytics. MATLAB provides a rich set of tools for data analysis, machine learning, and simulation. Its interactive environment is well-suited for developing and testing predictive maintenance algorithms.

- Alteryx: Alteryx is a data analytics platform that enables organizations to prepare, blend, and analyze data for predictive maintenance applications. It offers a visual interface for building workflows, making it accessible to users with varying levels of technical expertise. Alteryx supports the integration of machine learning models into the analytics workflow.

- KNIME: KNIME is an open-source data analytics platform that allows users to design and execute data workflows, including those for predictive maintenance. KNIME’s modular architecture enables the integration of various machine learning algorithms and tools. It is suitable for organizations seeking flexibility in building custom analytics workflows.

- SAP Predictive Maintenance and Service: SAP offers a predictive maintenance solution that integrates with its broader suite of enterprise software. SAP Predictive Maintenance and Service leverage machine learning to analyze equipment data, predict failures, and optimize maintenance schedules. It is designed to seamlessly integrate with SAP’s ERP and asset management solutions.

- Amazon SageMaker: Amazon SageMaker is a machine learning service provided by Amazon Web Services (AWS). It offers a complete set of tools for building, training, and deploying machine learning models at scale. SageMaker enables organizations to implement predictive maintenance analytics in a cloud environment, leveraging AWS infrastructure.

The choice of tools and platforms for predictive maintenance analytics depends on various factors, including the organization’s existing technology stack, the complexity of predictive models required, and the level of expertise within the data science team. Regardless of the specific tool or platform chosen, a successful predictive maintenance implementation requires a holistic approach that includes data quality, model interpretability, and integration with maintenance workflows.

database analytics for equipment health prediction is a transformative approach that empowers organizations to proactively manage the health and performance of industrial equipment. By harnessing the power of data, organizations can shift from reactive to predictive maintenance, optimize resource allocation, and enhance the overall reliability of critical assets.