Data Migration Strategies for Mechanical Databases

In the ever-evolving landscape of industrial operations, the need for seamless data migration in mechanical databases is a pivotal consideration. Whether transitioning to a new database system, upgrading existing infrastructure, or consolidating data from multiple sources, the process demands careful planning and execution. This blog post embarks on a journey through effective data migration strategies, best practices, and the keys to ensuring a seamless transition in mechanical databases.

Data Migration Strategies for Mechanical Databases

The complexities of mechanical databases necessitate thoughtful data migration strategies to ensure a smooth transition without compromising data integrity or operational efficiency. Let’s explore key strategies for data migration in mechanical databases:

Phased Migration Approach

Adopting a phased migration approach involves breaking down the migration process into manageable stages. This allows organizations to focus on migrating specific subsets of data or functionalities at a time. In the context of mechanical databases, where real-time data is critical for ongoing operations, a phased approach minimizes disruption and allows for thorough testing and validation at each stage.

Parallel Migration

Parallel migration involves running both the existing and new database systems concurrently during the migration process. This strategy ensures that operations continue seamlessly while data is migrated in the background. For mechanical databases handling continuous streams of data, parallel migration minimizes downtime and allows for a gradual transition, mitigating the risk of disruptions to critical processes.

Data Validation and Testing

Rigorous data validation and testing are integral to successful data migration. In the realm of mechanical databases, where accuracy is paramount, validating migrated data ensures that it aligns with the intended structure and integrity. Implementing comprehensive testing procedures, including data reconciliation and performance testing, helps identify and rectify issues before full-scale deployment.

Backup and Rollback Plans

In the unpredictable landscape of data migration, having robust backup and rollback plans is crucial. Before initiating the migration process, organizations should create comprehensive backups of the existing database to safeguard against unforeseen challenges. In the event of issues during migration, having a well-defined rollback plan allows for a swift return to the previous state while minimizing disruptions.

Database Migration Best Practices for Mechanical Systems

Database migration in the realm of mechanical systems demands adherence to best practices to ensure a seamless and secure transition. Let’s explore key best practices for database migration in mechanical systems:

Thorough Assessment and Planning

A thorough assessment of the existing database environment and meticulous planning are foundational to a successful migration. In the context of mechanical systems, where diverse data sources and real-time information streams are common, understanding the intricacies of the current database landscape is crucial. Detailed planning ensures that potential challenges are identified and mitigated proactively.

Data Cleansing and Transformation

Prior to migration, it’s essential to conduct data cleansing and transformation activities. In mechanical systems, where data quality directly impacts operational insights, cleansing ensures that migrated data is accurate and consistent. Transformation activities involve adapting data formats or structures to align with the requirements of the new database system, facilitating a seamless integration.

Engage Stakeholders and End Users

The success of a database migration project relies heavily on the engagement of stakeholders and end users. In mechanical systems, where data serves as the backbone of operations, involving key stakeholders and end users in the planning and testing phases is critical. Their insights and feedback contribute to the identification of specific requirements and help validate the effectiveness of the migration process.

Documentation and Communication

Comprehensive documentation and clear communication are essential throughout the migration journey. Documenting the migration plan, including steps, timelines, and dependencies, provides a roadmap for the migration team. Clear communication ensures that all stakeholders are informed about the migration process, potential impacts, and any necessary adjustments to workflows.

Strategies for Seamless Data Migration in Databases

Seamless data migration in databases is the hallmark of a well-executed transition. Strategies that prioritize minimal disruption, data accuracy, and efficient migration processes contribute to the seamless integration of data in mechanical databases. Let’s explore key strategies for achieving a smooth data migration experience:

Real-time Data Synchronization

For mechanical databases where real-time data is integral, employing real-time data synchronization strategies ensures continuous data flow during the migration process. This approach involves synchronizing data changes between the old and new databases in real time, minimizing the risk of data inconsistencies and supporting uninterrupted operations.

Incremental Migration

Incremental migration focuses on migrating data in small, incremental batches rather than attempting to move the entire dataset at once. This strategy is particularly effective for mechanical databases dealing with large volumes of data. By migrating data incrementally, organizations can maintain operational continuity and easily identify and address issues on a smaller scale.

Automated Migration Tools

Leveraging automated migration tools streamlines the migration process and minimizes the potential for human errors. In the context of mechanical databases, where precision is paramount, automated tools can efficiently handle data mapping, transformation, and validation tasks. Automated tools also contribute to the speed and efficiency of the migration process.

Post-migration Monitoring and Optimization

The migration journey doesn’t end with the completion of data transfer. Post-migration monitoring and optimization are critical for ensuring ongoing performance and data integrity. In mechanical databases, where continuous monitoring is essential, organizations should implement robust monitoring tools to track system performance, identify bottlenecks, and optimize configurations as needed.

Tools for Data Migration in Mechanical Applications

The success of data migration in mechanical applications hinges on the selection of appropriate tools. The market offers a plethora of tools designed to streamline the migration process, ensuring accuracy, efficiency, and minimal disruptions. Let’s explore notable tools that cater specifically to the unique challenges of data migration in mechanical applications:

AWS Database Migration Service (DMS)

Amazon Web Services (AWS) provides a robust Database Migration Service tailored for seamless migration to and from various database engines. In mechanical applications where precision is crucial, AWS DMS supports both homogeneous and heterogeneous migrations, allowing organizations to transition between different database types with ease. It offers features such as continuous data replication and automatic schema conversion.

Microsoft Data Migration Assistant (DMA)

Microsoft’s Data Migration Assistant is a versatile tool designed to assess the compatibility of databases and assist in migrating to newer versions of SQL Server. In the context of mechanical applications relying on SQL Server databases, DMA ensures a smooth transition by identifying potential issues and providing recommendations for remediation. It’s a valuable ally for organizations seeking to upgrade their database infrastructure.

IBM InfoSphere DataStage

IBM InfoSphere DataStage is a comprehensive ETL (Extract, Transform, Load) tool that excels in handling complex data integration scenarios. In mechanical applications dealing with diverse data sources, InfoSphere DataStage facilitates seamless extraction, transformation, and loading of data. Its visual interface simplifies the creation of data integration jobs, making it a powerful tool for intricate migration projects.

Talend Open Studio

Talend Open Studio is an open-source ETL tool that empowers organizations to integrate and migrate data across diverse environments. Particularly valuable for mechanical applications where interoperability is key, Talend supports a wide range of data connectors and formats. Its user-friendly interface and robust data transformation capabilities make it a popular choice for organizations seeking flexibility in their migration processes.

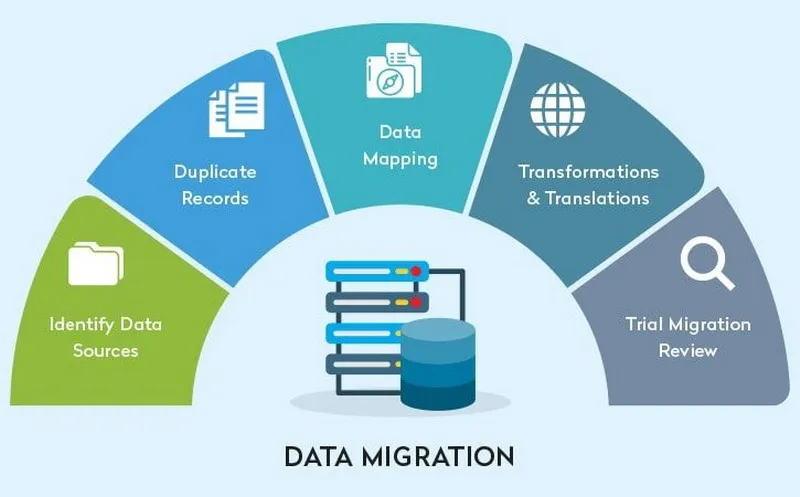

Data Mapping and Transformation in Migration

Data mapping and transformation play pivotal roles in ensuring that migrated data aligns seamlessly with the structure and requirements of the target database. In the realm of mechanical applications, where data precision is paramount, effective mapping and transformation strategies contribute to the success of the migration process. Let’s delve into key considerations:

Understanding Source and Target Structures

A foundational step in data mapping is a comprehensive understanding of both the source and target database structures. In mechanical applications, where data may be sourced from sensors, equipment logs, or diverse systems, mapping the relationships between source and target fields is crucial. This understanding forms the basis for accurate data transformation.

Data Cleansing and Standardization

Data mapping often involves cleansing and standardizing data to ensure consistency and accuracy. In mechanical applications dealing with sensor data or equipment logs, variations in data formats or units may exist. Data cleansing and standardization activities during mapping mitigate the risk of inconsistencies, laying the groundwork for a smooth transition.

Handling Data Transformations

Data transformations are central to the migration process, involving the conversion of data from one format or structure to another. In mechanical applications, where data may undergo changes in units, formats, or calculations, robust transformation strategies are essential. Whether it’s converting temperature values, aggregating sensor data, or recalculating metrics, meticulous transformation ensures data accuracy post-migration.

Testing and Validation

Rigorous testing and validation are integral components of the data mapping and transformation process. In mechanical applications, where precision is paramount, validating transformed data against expected results is crucial. Thorough testing, including sample data validation and end-to-end testing, helps identify and rectify issues before the full-scale migration.

Case Studies on Successful Database Migration in Mechanical Engineering

Real-world case studies offer valuable insights into the challenges and triumphs of database migration in the field of mechanical engineering. Let’s explore two compelling case studies that showcase successful migration endeavors:

Case Study: Automotive Manufacturing Database Migration

Challenge:

A leading automotive manufacturer faced the challenge of upgrading its legacy database system to a modern, scalable solution. The legacy system struggled to handle the influx of real-time data from production lines and sensor networks, leading to performance bottlenecks.

Solution:

The migration team opted for a phased approach, migrating critical production data first. Microsoft Data Migration Assistant (DMA) was employed to assess compatibility and provide recommendations. Data mapping and transformation focused on optimizing the structure for real-time analytics.

Outcome:

The phased migration resulted in minimal disruptions to production operations. Real-time data processing capabilities improved, allowing the manufacturer to gain immediate insights into production efficiency and quality metrics. The success of the migration positioned the company for future scalability and innovation.

Case Study: Aerospace Equipment Monitoring System Migration

Challenge:

An aerospace engineering firm relied on an outdated database system for monitoring critical parameters of its equipment. The legacy system lacked the agility to handle increasing data volumes and posed a risk to the accuracy of equipment health assessments.

Solution:

The firm chose IBM InfoSphere DataStage for its ETL capabilities and flexibility. Data mapping involved restructuring equipment parameters for enhanced analysis. Incremental migration ensured continuous monitoring during the transition, and automated validation scripts were implemented for accuracy checks.

Outcome:

The migration resulted in a more robust equipment monitoring system. Real-time alerts were optimized, and the system could handle a broader range of data sources. The aerospace firm experienced improved equipment reliability and reduced maintenance costs, showcasing the impact of a well-executed migration.

In the intricate landscape of mechanical applications, the journey of data migration requires strategic planning, precise execution, and the right set of tools. Navigating the challenges involves leveraging tools designed for mechanical applications, mastering data mapping and transformation, and drawing inspiration from successful case studies. As organizations embark on the path of database migration in mechanical engineering, the lessons learned from tools, mapping, and real-world experiences pave the way for enhanced efficiency, accuracy, and innovation in data management.

Conclusion

In the intricate landscape of mechanical databases, the art of data migration requires a delicate balance between precision, planning, and execution. By embracing phased approaches, adhering to best practices, and implementing seamless migration strategies, organizations can navigate the complexities of data migration with confidence. The keys to success lie in meticulous planning, stakeholder engagement, and a commitment to continuous improvement, ensuring that the transition to a new database landscape is not just a process but a seamless journey toward enhanced operational efficiency.