An Approach to Building an Autonomous Smart Factory

Last Updated on April 5, 2023 by Mutiara

This article describes an approach to achieving a high level of autonomy in an assembly factory that differs from standard factory automation practice. In our approach, decisions are made based on real-time data and without human intervention.

The article begins with a brief review of the literature.

The second chapter discusses the difference between autonomy and automation.

The third chapter defines modern manufacturing and describes the processes most suitable for automation.

The fourth chapter presents the concept of autonomous control of logistics and mobile robots.

The approach itself is described in the fifth chapter, which also discusses the key logical elements of autonomous control systems.

The sixth part presents the software tools and technologies used to create an autonomous factory.

In conclusion, the ideas presented and the advantages of the proposed approach are summarized.

1. Literature review

In recent years, the adoption of autonomous systems in various factories has been on the rise as companies look to improve efficiency and reduce costs. This literature review reviews the current state of research on autonomous systems for factories, including benefits, challenges, and future trends.

Advantages:

Primary analysis proves that off-grid systems offer numerous benefits for plants, including increased efficiency, reduced downtime, and improved product quality. For example, one study [1] shows that the introduction of an offline material handling system in a plant resulted in a 30% reduction in downtime. Another study [2] states that the use of autonomous guided vehicles (AGVs) in a factory leads to a 20% increase in production efficiency.

Challenges:

Although the theoretical advantages of autonomous systems are clear, there are also a number of problems associated with their implementation. The three main problems are the cost of deploying autonomous systems, traditional factory architectures that are not compatible with modern approaches in software (modularity, micro-service approach, etc.) and resistance to change by employees. It has been found [3] that the costs of implementing an AGV system in a plant can be higher than those associated with traditional material handling systems. Another study [4] concluded that employee resistance to change can be a major barrier to the successful implementation of autonomous systems. In addition, it was found [5] that the creation of an autonomous system.

Future trends:

The future of autonomous systems for factories will obviously be determined by technological advances such as the development of artificial intelligence and the IoT. For example, a study [6] showed that integrating artificial intelligence into autonomous systems can significantly improve their decision-making ability and reduce the need for manual intervention. Another study [7] concludes that the use of IoT technology can allow autonomous systems to communicate and cooperate with each other, which will lead to an increase in the efficiency of production processes.

2. Autonomy versus automation

To better illustrate the autonomous factory concept, it is important to distinguish between autonomy and automation. Autonomy means the ability of a system or object to act independently, without external control or influence. It can refer to a wide range of objects, from individual organisms to complex machines and systems. In the context of artificial intelligence, the term “autonomy” is often used to describe the ability of a machine or software system to make decisions and act independently, without direct human intervention.

On the other hand, automation is the use of technology to perform tasks that were previously performed manually by humans. This can include everything from simple, repetitive tasks such as assembly line production to more complex processes such as data analysis and decision making. Automation can help improve efficiency, accuracy, and speed; in addition, by freeing employees from repetitive work, automation allows them to focus on more creative and strategic tasks.

2.1. Autonomous systems

Autonomous systems are systems that are capable of performing tasks or making decisions without human intervention. These systems rely on artificial intelligence (AI) and machine learning to learn by themselves, interacting with the environment and adjusting their behavior accordingly. Examples of autonomous systems are self-driving cars, drones, and assistant robots. Such systems are able to process large amounts of data and make decisions based on them in real time.

The benefits of autonomous systems include improved safety, efficiency, and accuracy. Self-driving cars can reduce the risk of human error while driving, which is the main cause of accidents. Autonomous drones can be used to perform tasks such as surveying, mapping and delivering goods, which can be faster and more cost-effective than traditional methods.

However, autonomous systems also have potential disadvantages. First, they may be prone to error in difficult situations and make decisions based on incomplete or incorrect information. In addition, they raise privacy and security concerns as such systems collect and transmit large amounts of data.

2.2. Automated systems

On the other hand, automated systems are designed to perform tasks that a human would otherwise perform manually. They aim to streamline and optimize processes such as production, data analysis and customer service.

Examples of automated systems are assembly line robots, chatbots, and accounting software. These systems can complete tasks faster and more accurately than humans and can operate continuously without interruption or fatigue.

The benefits of automated systems include increased productivity, accuracy, and economy. For example, manufacturing robots can produce goods faster and with fewer defects than human workers, resulting in improved product quality and helping to reduce costs. Chatbots can serve customers around the clock, increasing customer satisfaction and reducing the burden on support staff.

At the same time, automated systems may raise concerns about job displacement, as they may completely eliminate the need for human workers in some industries. In addition, they may have limitations in their ability to deal with difficult or unexpected situations.

2.3. Differences between autonomous and automated systems

The key difference between autonomous and automated systems is that autonomous systems are designed to make decisions and actions on their own, while automated systems are designed to complete tasks faster and more accurately than a human. Autonomous systems rely on AI and machine learning, while automated systems rely on technology such as robotics and software.

Autonomous systems tend to be more complex and sophisticated than automated systems, and their scope is much broader. However, they are also more error prone and may require more oversight and regulation.

Automated systems are generally simpler and clearer than stand-alone systems, and can be used in a wide variety of industries and applications. However, they may not be able to handle complex or unforeseen situations, and they may not be suitable for tasks that require creativity or human judgment.

3. Modern factories and factory processes

Now consider the key features and methods of operation that define a modern factory. The following are the features that characterize modern automotive production:

- Automation and Robotics: Modern automobile factories are equipped with robots and are highly automated; this leads to increased efficiency, reduced labor costs and improved production accuracy.

- Cutting edge technology: The modern factory uses data analytics and IoT to improve production efficiency, quality and safety.

- Lean Manufacturing: The lean manufacturing approach emphasizes continuous improvement, waste reduction, and efficient use of resources.

- Security: Includes the installation of security sensors, protective equipment and automated security systems.

- Sustainable Manufacturing: Technologies and practices that reduce environmental impact, such as recycling, waste reduction, and the use of renewable energy sources.

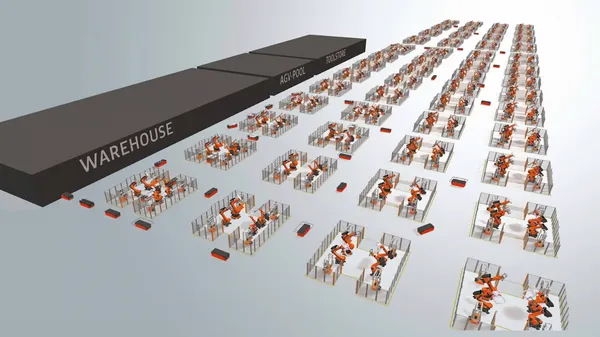

( https://www.kuka.com/en-de/industries/solutions-database/2016/10/matrix-production )

Efficient, consistent and high-quality production relies on a set of core practices that also help reduce costs and minimize the risk of accidents. Let’s also look at which processes are critical for a modern and autonomous factory:

Quality Control: In the automotive industry, quality control is a very complex process where specific methods can vary and include many checks, tests and audits to ensure that products meet the required standards.

Inventory Management: Critical to any business as it helps ensure that the right materials and supplies are available when they are needed. Includes tracking inventory levels, managing supplier relationships, and forecasting future demand.

Security: Regular employee training, risk assessment and security checks.

Maintenance: Helps keep equipment and machines operating at optimum levels and extending their life through regular inspections, preventive maintenance and equipment upgrades.

Production planning: Includes demand forecasting, production scheduling and capacity control.

Continuous Improvement: Helps identify and implement changes that can improve production efficiency. Main components: data analysis, process mapping and comparative analysis.

Employee Training: Providing staff with the skills and knowledge they need to perform their jobs effectively – bringing in newcomers, ongoing training, and evaluating performance.

4. Autonomous management of the factory logistics system

The logistics system here refers to mobile robots, or AGVs – cargo carriers that help transport materials or manufactured parts around the enterprise. The following is a summary of the main AGV management processes:

- Selecting AGVs: The first step is to select suitable AGVs for the tasks they are to perform. This takes into account factors such as the size and weight of the cargo being transported, the type of plant, production processes, and most importantly the required speed and accuracy of the AGV.

- Autonomous control: The main difference between autonomous and traditional AGV fleet control lies in the level of control that is required from the human operator. Autonomous AGVs are equipped with sensors and cameras that allow them to navigate and operate independently. Reducing the need for manual labor makes production more cost effective.

- Predictive Maintenance: Autonomous AGV fleet management software enables predictive maintenance. It uses the data it receives from the AGV to determine when maintenance might be needed and schedule it accordingly. This helps reduce AGV downtime and eliminates the negative impact of equipment breakdowns on plant operations.

- Route Planning and Optimization: These are the processes of calculating and optimizing efficient routes to be followed by mobile robots. Efficient routing increases the throughput of the logistics system and the output of the entire factory.

- Real-time monitoring: With dedicated software, factories can monitor AGV performance, status, location, speed, etc.

- Data analysis and reporting: Data analysis and reporting software to get quantitative information about fleet performance. Includes indicators such as: the number of mobile robots involved, the distance traveled, collisions, energy consumption, the amount of time spent on maintenance, etc. This data is part of the Bigdata factory and is used for further optimization.

- Autonomous Decision Making: Some control systems allow autonomous decision making for AGVs. Using a set of algorithms, the software analyzes the data coming from the sensors of mobile robots (lidar, load, computer vision) and adjusts the speed or route of the AGV in real time. This improves the efficiency of the logistics system and reduces the need for manual intervention.

5. How to create an offline factory

5.1. Goals for Autonomous Control System

The same control principles that we used to control mobile robots can be applied to building an autonomous factory. Extending autonomous control to the level of an entire plant or even a group of plants allows:

- Increase Efficiency: Fewer people involved in the decision-making process mean fewer errors and less cost to run a plant. Management optimization can reach 40-50%

- Increase safety: It is obvious that by reducing operations that require a person, we increase the level of safety.

- Multiply the quality and speed of monitoring and decision-making: By integrating multiple sensors, cameras and other monitoring devices into the factory environment, factories can collect a huge amount of data about production processes, equipment status, product quality, etc. Autonomous algorithms allow the factory to independently analyze and make real-time decisions.

- Flexibility and scalability: Autonomy implies the ability of the system to independently rebuild and reconfigure equipment and processes in the event of changes (new product, failure, upgrade, etc.). This reduces the cost of responding quickly to market changes and customer needs.

In order to build a stand-alone factory with similar characteristics, we, the Robofacturing team at Arrival, have developed a special control system.

5.2. Autonomous control system

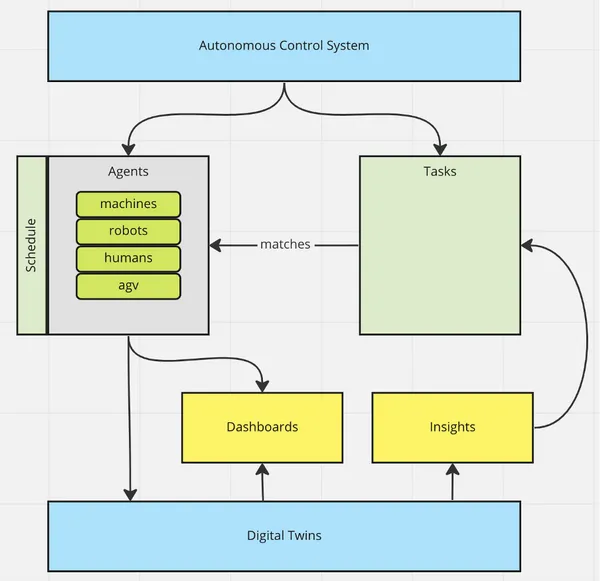

With regard to logic, the autonomous control system consists of the following elements:

- Agents / Resources;

- Their schedule;

- Digital twins of agents and factory processes;

- Control system based on artificial intelligence;

- Insights, which also function as Tasks (recommendations) used to improve processes;

- Dashboards (dashboards).

The block diagram below illustrates the logical architecture of the system and the relationship between its elements. First, the control system creates jobs and distributes them among agents. Each agent has its own task schedule and works using Digital Twins real-time data and dashboards. Dashboards are also built in real time based on data collected from digital twins. Inputs and conclusions also come from “digital twins” and are formulated in the form of tasks, where each task has its own set of conclusions (data).

Now let’s take a closer look at each of the elements.

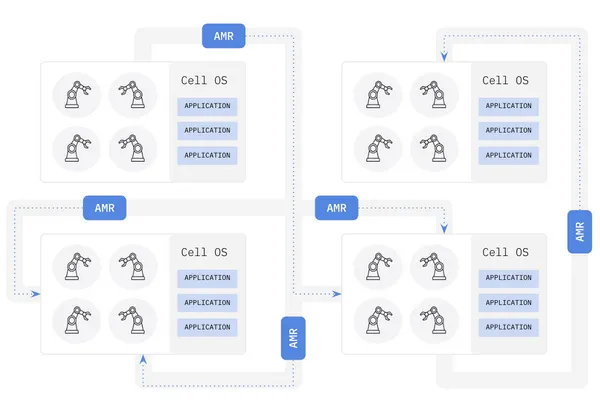

5.2.1. Agents

Technically, autonomous agents are programs that work independently and perform tasks on behalf of a user or another program. These agents can interact with the environment, make decisions, and take actions without human intervention. In practice, we consider all active physical or virtual objects involved in the production process as agents. This includes mobile robots (AGVs), industrial robots, machines, automated cells, decision services, monitoring services, and workers. All decisions that agents make are based on data and algorithms. Consider a few examples of autonomous agents:

- Mobile robots, which can perform logistical tasks, determine their path, detect and avoid obstacles, schedule charging or maintenance;

- Automated scheduling systems, which use algorithms to analyze production flow data and execute scheduling algorithms to optimize throughput;

- Industrial robots, which perform tasks such as assembly, welding, and painting in a manufacturing environment.

After defining the Agents, the next step is to define the tasks they should perform.

Each Agent is characterized by a set of skills, or abilities – abilities. The autonomous control system acts as a broker, matching the tasks it receives from the outside with the capabilities of the Agents. In case of a match, the task is assigned to the Agent. Here are some examples of tasks in a factory:

- Logistics tasks, such as moving materials to a specific location on a facility;

- Assembly tasks, for example, assembling a specific set of components using specific connections (welding, gluing, etc.);

- Maintenance tasks, such as performing the replacement of a broken tool in a robotic cell;

- Quality tasks, for example, computer vision measurements of the assembled product for compliance with tolerances;

- Manual assembly tasks, such as fixing screws.

Considering human workers as autonomous agents may seem controversial. In our concept of autonomous production, we consider a factory worker equipped with a tablet computer as a biorobot. Such a worker receives tasks from the control system and performs actions (operations) based on data provided by the system in real time, such as task definitions, equipment status (for maintenance), sequence of actions, available tool, etc. For an autonomous factory, the concept of Human machine interface should be replaced by Machine Human interface – thus reflecting who (in our case, What) makes the decision and issues commands.

5.2.2. Schedule

The scheduler is an autonomous system that monitors all data in real time (eg tasks, agents, hardware status) and makes changes to the schedule if necessary. Scheduling algorithms work by determining the order in which tasks should be processed based on a set of constraints and goals. Such restrictions may include:

- The presence of an agent;

- Lead times for each production order;

- Dependencies between tasks (for example, a build task can only be started after a logistical delivery task has completed).

The goal of the algorithm is to minimize the time it takes to complete all tasks, or maximize the use of resources.

There are several types of scheduling algorithms, including:

- First in, first out (FCFS) scheduling: This is a simple algorithm that processes jobs in the order they were received. It is simple to implement, but can be inefficient if tasks have different processing times.

- Smallest Job First (SJF) scheduling: This algorithm runs jobs in the order of their estimated processing time, with the shortest jobs processed first. This may be more efficient than FCFS, but may not be optimal if longer tasks have a higher priority.

- Round Robin Scheduling: This algorithm processes tasks in a round-robin fashion, with each task given a fixed amount of time before it is preempted and moved to the back of the queue. It is commonly used in time-sharing systems.

- Priority scheduling: This algorithm processes tasks based on their priority level, with higher priority tasks processed first. It can be efficient for handling urgent tasks, but it can be unfair to lower priority tasks.

- Deadline scheduling: This algorithm processes tasks based on their due dates, with the earliest due processed first. It is typically used in real-time systems where meeting deadlines is critical.

We suggest using a combination of priority and deadline scheduling, as well as real-time process simulations to avoid dead ends and collisions.

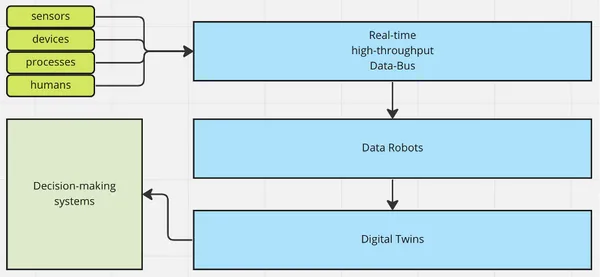

5.2.3. Digital twins

In our factory, we have built a system that stores data, links it to the digital twin via information robots, and delivers the data to consumers in real time with a latency of less than 100ms. In this way, consumers (primarily other robots) are always aware of what is happening on the production floor and can make more accurate decisions.

The decision-making system in this case consists of:

- The control system itself;

- All autonomous agents;

- Scheduler;

- Mechanism Insights.

A more detailed description of the concept of Digital Twins is presented in a separate article “ What are Digital twins and how they help create an autonomous factory”.

5.2.4. Control system

We use a rule-based multi-agent AI system to manage production. Briefly, a rule-based system is a computer program that relies on a set of predetermined rules and conditions to make decisions. These rules are based on the specific goals and objectives of the system and are used to evaluate and prioritize information and data.

This approach is especially useful for manufacturing, as it can be easily applied to production, planning, and inventory management decisions while providing greater accuracy than Machine Learning (ML) algorithms. The second important advantage is repeatability.results. The results obtained by ML algorithms may differ each time they are run, even if the same input is used. Rule-driven systems always produce consistent results. The third feature is the absence of predefined, finite options for sequences of operations (tasks) and automatic restructuring of the solution at each moment of time under the influence of the actions of the Agents. These 3 factors, accuracy and repeatability, are manufacturing imperatives, i.e. define an autonomous factory.

5.2.5. Conclusions

Insights is a set of data algorithms that analyze the flow of data produced by digital twins (i.e. changes in their state) and generate tasks as needed, such as predictive maintenance or quality control tasks. Insights can vary from factory to factory and are always customizable.

5.2.6. Dashboards

Dashboards are also built from Digital Twins data, but presented in a form that best facilitates decision making. For example, a maintenance dashboard displays data about the general condition of the equipment and its maintenance history: tasks, failures, downtime, etc. The dashboard for the quality inspector should include information about the product being inspected and a description of the assessment procedure. Like any BI system, dashboards should be available for customization by a non-programmer. Ideally, Human Agents should be able to build their own dashboards by combining different types of data from the Digital Twins repository.

6. Software products and technologies

The autonomous platform project uses the following technologies:

- Scala

- AkkaHTTP

- Zio

The Scala language was chosen for development. it contains high-performance, well-paralyzed frameworks. Initially, the choice fell on Akka Actors. A kind of green thread from Erlang. We passed the stage of both non-typed actors and moved to typed ones. The idea was very simple: each autonomous platform agent is an actor. At the same time, there can be hundreds of thousands of actors, because Every function, every listener is an instance of some actor. As a result, such a computational model turned out to be not very efficient, since no more than a couple of hundred processes are running in parallel at the same time, and tens of thousands of actors are simply idle and listening when they receive messages. As a result, ideas from directed Petri nets were taken as a computational model [ https://en.wikipedia.org/wiki/Petri_net]. ZIO was chosen as a framework because. It is great for the task of synchronizing and exchanging events for many parallel processes.

The data platform is simpler in terms of frameworks. We use Scala and CATS framework. Scala is selected – because I did not want to have a different stack in two related projects. Well, CATS is a great framework for simplifying code. At the same time, the data platform accumulates many data management technologies, among them: Kafka, RabbitMQ, MongoDB, ClickHouse DB, Parquet, Spark, Kafka streams, MinIO. Many other bases were also tested, but so far settled on the stack indicated above.

7. Conclusion

In summary, autonomous systems for factories have the potential to significantly improve efficiency, production quality, and flexibility. The future of autonomous systems in manufacturing will be determined by the development of technologies, namely AI and IoT.

In this article, we outlined an approach to the implementation of an autonomous control system in enterprises, where the key elements of logic are agents, schedules, digital twins, a control system, insights and dashboards. The proposed method uses artificial intelligence technologies applied to digital twin data. Combined with industry best practices for production management, this approach allows you to build an advanced fully autonomous production.

Source

- Agrawal, Gaurav K., and Sanderesh S. Kheragu. “Review of automated material handling systems in 300mm semiconductor fabs”. IEEE Transactions on Semiconductor manufacturing 19.1 (2006): 112-120.

- Behtzis, Dimitrios et al. “Sustainable Supply Chain Management in the Digital Age: The Impact of Automated Guided Vehicles”. Journal of Cleaner Production 142 (2017): 3970-3984.

- Silva, Tomé, et al. “Modeling and economic analysis of the AGV system as a means of transporting warehouse waste in the automotive OEM.” 2016 IEEE 19th International Conference on Intelligent Transportation Systems (ITSC). IEEE, 2016.

- Saraf, Jayant V., and Richard J. Sebastian. “Human Resource Strategies for Effective Implementation of Advanced Manufacturing Technologies (ATT)”. Journal of Production and Inventory Management 33.1 (1992): 64.

- Alexandru, Matei, Circa Dragoș, and Zamfirescu Bălă-Constantin. “Digital Twin for Automated Guided Vehicle Fleet Management”. Procedia Computer Science 199 (2022): 1363-1369.

- Kovacs, György, Rabab Benocmane and Laszlo Dudas. “The concept of autonomous systems in Industry 4.0”. Advanced Logistic Systems-Theory and Practice 12.1 (2018): 77-87.

- Macher, Georg, et al. “The quest for infrastructures and engineering methods enabling highly dynamic autonomous systems.” Systems, Software and Services Process Improvement: 26th European Conference, EuroSPI 2019, Edinburgh, UK, September 18-20, 2019, Proceedings 26. Springer International Publishing, 2019.